Every cutting insert experiences a drop in performance as it approaches the end of its performance life. If this condition goes undetected for any amount of time, the part-machining performance as well as part quality may have suffered already.

To make matters worse, some shops will continue to push the worn tool to its limit – where it’s likely to fail in the middle of a critical process. While a failed cutting insert is the least of a shop’s problems, damage to the workpiece is the much more significant issue.

However, if shop managers or operators are able to identify the extent of insert wear quickly and easily, they can replace it in a timely manner and avoid any damage to tools or parts. What makes this possible are advances in cutting tool coatings that, essentially, warn shops of impending insert disasters.

Such coatings typically involve multiple layers, the top one of which provides the early-warning wear detection while the others ensure optimum performance and longer tool life. The effectiveness of these coatings, however, also depends on how they are applied. In most instances, special mechanical post-treatments are used and will ensure the layer surface's unique state of residual stress, which then pays off in terms of increased process security, especially in large-scale production operations.

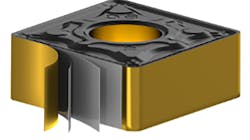

To prevent insert waste and easily detect wear, the gold-colored TiN outer layer of the Dragonskin multilayer CVD Ti(C,N)/Al2O3/TiN coating from cutting tool OEM CERATIZIT, for example, acts as an indicator. It not only enables users to clearly identify insert wear and index before a breakage, but also prevents sharp cutting edges from going unused and the insert being inadvertently discarded.

For the Dragonskin coating, the company not only incorporated the three-layer approach and mechanical post treatments, but it also applied these to indexable insert grades engineered specifically for the intended part material applications. One example is CERATIZIT’s recently released ISO-P steel turning inserts featuring the Dragonskin coating, which extends the working life of the new inserts by as much as 20 percent, when compared to their predecessors.

ISO-P steels are by far the largest material group in part machining, and includes materials from ductile, low-carbon steels to high-alloy steel grades. Added to this are variations in hardness, application types and machining conditions during the turning operation. To make choosing an appropriate indexable insert grade easier, the turning specialists at CERATIZIT have developed their own indexable insert grades and tailored these to the wide variety of ISO-P materials.To enhance productivity for its customers CERATIZIT rethought its new CTCP135-P, CTCP125P-P and CTCP115-P turning grades from the substrate to the geometries and through to the Dragonskin coating. This was done to optimize process security and hardness of insert edges to ensure they withstand extreme cutting-zone temperatures without plastic deformation. This also ensures that the inserts handle a full range of machining challenges, such as when materials are extremely hard or tough.

Each of the three grades are engineered for optimizing specific production scenarios. The CTCP115-P (ISO P15) grade has enhanced resistance to elevated temperatures and is ideal for use at higher cutting speeds in smooth, continuous cuts in stable cutting conditions.

The CTCP125-P (ISO P25) universal steel-cutting grade balances toughness and wear-resistance to provide consistent reliability in turning operations, ranging from finishing to rough machining, while the CTC135-P (ISO P35) is a tough carbide grade for lower cutting speeds, interrupted cuts, and unstable machining conditions.

Machining steel is anything but easy, and most experienced machining specialists are open to any solution that helps them turn ISO-P steel. This is why CERATIZIT continues to refine its insert grades and apply its Dragonskin coating to prevent waste, extend tool life and further ensure a shop’s overall long-term success. Those shops that fail to evaluate new alternatives and best-practices when selecting an indexable insert grade will be squandering the potential for considerable savings.

Robert Bokram is the Product Manager, Cutting Tools, at CERATIZIT, manufacturers of hard material products for wear protection and cutting tools.

About the Author

Robert Bokram

Product Manager, Cutting Tools

Robert Bokram is the Product Manager, Cutting Tools, at CERATIZIT, manufacturers of hard material products for wear protection and cutting tools.