Making Automated 3D Part Inspection a Competitive Advantage

Whether manufacturers pursue lean production, maintain Six Sigma processes, or implement a quality-assurance program of their own, measuring is at the heart of quality control and it’s a foundational element of Six Sigma’s goal to Define Measure Analyze Improve and Control (DMAIC) production processes. Yet, excess waste remains after the measurement is completed by slow, human subjective means, such as traditional hand gauges and optical comparators, which can promote a myriad of errors in production processes.

With manual methods, first-part inspection can take up to 45 minutes, incoming inspection audits can take hours, and the Production Part Approval Process (PPAP) can take days. Obviously, accuracy can be less than desired.

“Even if micrometers and calipers are calibrated properly, measurement will vary from person to person depending on how they are held, squeezed, and interpreted,” said Rocky Pinheiro, Ph.D., v.p. of Quality, North American Operations at Acument Global Technologies, a manufacturer of value-added screws, bolts, nuts and cold-formed components for automotive, industrial, aerospace, and defense manufacturing.

Inspection equipment that provides a two-dimensional (2D) or cross-sectional view of parts also may be insufficient for today’s demanding quality control

requirements. “Parts do not exist in a 2D, but a 3D world,” Pinheiro commented. “Every part manufactured must properly mate and function with other components in three dimensions.”

For these reasons, proactive manufacturers are turning to precise, objective, inline 3D inspection that can measure and record dozens of part features in a fraction of the time it would take to do manual inspection. This is enabling manufacturers to turn automated 3D part inspection into a competitive advantage that is capable of significantly increasing quality and cycle time, reducing scrap, and improving overall equipment efficiency up to 20%.

Automated 3D Part Measurement

“With LaserLab we are completing up to 20 measurements per part in three dimensions within 30 seconds for first part, hourly, and final inspection,” said Pinheiro. “It gives us feedback on 90% of the elements we want to measure. From length, diameter, radius, and head height to corners, shoulders, and other dimensions it is very accurate.”

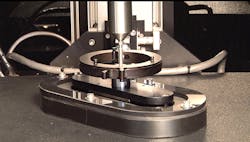

LaserLab is a three-dimensional laser gauging system offered in in laboratory and shop-floor versions. It can measure over 20 critical part features down to 2 microns in diameter within 20 seconds. It’s available from General Inspection, a developer of high-speed measuring and fastener inspection sorting systems.

“We are seeing a 10-20% improvement in overall equipment efficiency (OEE) for set up and changeover, and are making parts much faster with LaserLab,” according to Pinheiro. “We are also significantly reducing first time scrap and downstream sorting while increasing production cycle time.”

Because the patented laser technology accurately measures with exact repeatability every time, it reduces part-to-part variability significantly by eliminating operator error. A comprehensive, built-in thread database provides instant tolerances for each thread characteristic, and after every pass the laser beams are automatically calibrated to NIST standards to ensure accuracy.

As such, LaserLab provides real-time manufacturing process control with more precise, repeatable measurements than possible manually. This allows more frequent part measurement that significantly improves product quality and reduces scrap.

According to Pinheiro, Acument Global Technologies previously used operator manual inspection to determine first part quality, which required about 10 minutes to check part dimensions.

“Using the 3D laser gauging system has cut our inspection time to less than 30 seconds per part, a twenty-fold time savings,” Pinheiro said. “We ensure our process is performing within specifications so we’re continuously manufacturing good parts.”

True to Lean

True to the tenets of lean product and Six Sigma, the 3D laser gauging system has streamlined accurate data collection and statistical process control (SPC), placing Acument Global Technologies in a virtuous cycle of better production measurement, analysis, improvement, and control.

“Instead of operators hand measuring part dimensions and writing the data on paper to enter in Excel, LaserLab’s output goes directly into Excel electronically,” he said. “This eliminates operator bias, error, as well as the production bottleneck of operators stopping to measure product, which allows us to manufacture with more continuous flow.”

As Acument Global Technologies begins using LaserLab for incoming-part identification and validation at distribution centers, Pinheiro expects to see further benefits: The process will verify that the correct parts are actually in the containers; and it will verify critical part characteristics, such as length, diameter, flats, corners and head height.

“We have found that the 3D laser gauging system reduces incoming part identification and validation cycle time from 3-4 minutes to about 20 seconds,” Pinheiro explained. “The efficiency allows staff deployment to other areas while ensuring part quality and accuracy for our end customers.”

While the Acument’s PPAP process typically took about 90 minutes to measure several parts with manual gauges, such as micrometers or calipers, LaserLab has saved about one hour per PPAP. “The efficiency has freed up about a day per month for my PPAP coordinator to further enhance quality control,” Pinheiro estimated.

He also said Acument is realizing very strong EBITA (“Earnings Before Interest and Taxes Accrued”) performance, compared to last year’s results. “This tells me that even if we are not directly measuring some the benefits of the 3D laser gauging system they are flowing to the bottom line,” he said.

“Any company that manufactures parts where dimensional accuracy is crucial should look into a 3D laser gauging system,” Pinheiro concluded. “We achieved ROI in one year on our units and are still realizing greater efficiencies.”