Robot Loads in productivity

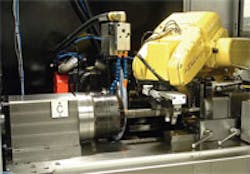

A sophisticated robot load/unload system increases the throughput of ground threads on the GS:TE-LM thread grinder from Drake Manufacturing (www.drakemfg.com) and eliminates coolant mess. The load/unload system also eliminates the need to fence in the robot when the machine is located in a work cell.

The auto load system consists of an infeed conveyor that can be configured for either side of the machine, a robot with dual grippers and an exit conveyor.

The infeed conveyor and grippers provide the fast changeovers between families of parts. Changeovers take just minutes because robot cycles are coordinated with Drake’s PartSmart programs.

The pre-programmed robot load system automatically responds to part dimension changes, working off new part information that was entered in the menu during the changeover. When cycling, the robot loader lifts a new blank off the infeed conveyor and deposits a finished part on to the exit conveyor simultaneously.

The GS:TE-LM is a full helix thread grinder equipped with a host of advanced machine and grinding technologies, including a 180-degree power helix, linear motor and ways, a Fanuc control programmed with customer parts, acoustic touch dressing, automatically generated wheel forms and a mineral-filled cast-polymer base. The machine grinds taps, multi-start worms, electronic steering components, fast lead ballscrews, feed and bone screws, gear boxes, transmissions and speed reducers.