Optimizing Machine Tool Spindle Performance

Machine tool spindles in all their designs and sizes represent highly advanced technology essential to key operations on the shop floor. They are routinely used to rotate cutting tools, grinding wheels, or parts to be machined, in applications ranging from milling, drilling, and boring to grinding, cutting, and sawing. Spindles have become complex systems integrating dozens of components critical to machine tool performance.

When a machine tool spindle fails to perform properly – or breaks down altogether – suspicion may fall to any number of causes. The detective work should begin with a focus on the basics:

- Was the spindle incorrectly assembled, stored, handled, or installed?

- Is the spindle being used in an application for which it was not intended?

- Did external conditions or influences contribute to the problem?

From there the investigation can advance by focusing on defects in the spindle, which will provide the clues to uncover the root cause of failure and, ultimately, make the appropriate fix.

No component of a spindle will be immune from potential failure over time, especially with relentless demands on spindles for sustained productivity. When a machine tool spindle fails, the expertise of skilled technicians with in-depth knowledge can provide a big assist by providing optimized repairs and rebuilds, and getting the spindle back on track.

Success stories from operations that have turned to SKF for spindle repair, remanufacturing, and/or rebuilding services, demonstrate real-world value.

Case in point: Integral collet

Relatively expensive repairs repeatedly were required by a customer to correct damage to a spindle shaft. Historically, damaged shafts cannot easily be repaired and usually must be replaced entirely. Analysis determined that the shaft’s integral collet-like end was causing the headaches.

Solution:An all-new design featuring a conversion offered more options, improved accuracy, and less chance for needing a shaft replacement. The shaft was replaced with a collet-type nose that can accommodate several sizes, and often can be repaired easily. This conversion did the trick.

Case in point: Chatter, coolant ingress

Another spindle was failing every few weeks. Prior to failure, chatter could be heard and ingress of coolant was noticed. Attention turned both to the spindle’s bearings and seals, and investigation showed that standard bearings originally used in the spindle’s design were inappropriate and that at least one seal in front of the spindle was virtually useless.

Solution:Four pairs of properly specified angular contact ball bearings were installed, five new seals were integrated, and most of the spindle’s components were completely reworked. As a result, the spindle performed without incident for more than 16 months compared with a previous Mean Time Between Failure (MTBF) of only several weeks.

Case in point: Inaccurate tool interface

One of our customers reported that a spindle’s existing tool interface was not fulfilling required accuracy and repeatability demands for the application. In addition, the design was inefficient for tool changes. Compounding the problem, coolant contamination was leading to frequent spindle failure. (This was because the spindle was positioned in a nose-up configuration allowing the coolant to flood over the top of the spindle.)

Solution: The spindle’s shaft design was changed to a manual HSK (hollow shank tooling), which provided a very accurate, quick, and easy tool change that delivered the desired repeatability. Then, the spindle’s front cap was redesigned and replaced with a rotating slinger that dispenses the coolant away from the spindle and keeps it at bay. These improvements resulted in much better performance, greater efficiency, and a five-fold increase in MTBF.

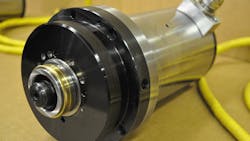

This spindle typically operated for a month or so before it required maintenance, but since it was updated and upgraded with better seals (also shown) it has been running well for several years.

Machine tool spindles can be remanufactured cost-effectively many times over with attention focused squarely on the parts or components causing problems. When turning the spindle over for repairs, the time also may be right to consider upgrading or otherwise customizing the spindle to realize improved performance, gain greater versatility, and/or accommodate new or changing application requirements. Making an upgrade while a spindle is already down and due for repair makes economical sense and makes the most of an opportunity.

Some upgrades for spindles can be relatively simple to implement, while others may become more involved. All can help to improve upon spindle performance and operation. Some examples:

• Potential upgrade: Convert from all-steel bearings to hybrid bearings, integrating silicon nitride (ceramic) rolling elements. This can allow a spindle to run at higher speeds and at lower operating temperatures.

• Potential upgrade: Increase or decrease the preload to the bearing setup to enable a spindle to run faster at higher RPM or to gain rigidity and run slower at lower RPM, based on requirements.

• Potential upgrade: Change bearing configurations to create a faster or more rigid spindle.

• Potential upgrade: Change a pulley style from a flat belt to a Polly “V” for better tracking, less slip, and more power to the spindle.

A need to protect spindles in very high contamination areas suggests other possible upgrades that will deal with sealing systems and air purges to keep contaminants (such as coolant, water, oil, metal, aluminum, grinding grit, and any material being machined) from entering the spindle and destroying the bearings.

Case in point: Coolant clogging, lubrication system problems

An operation was experiencing repeated incidents of motor coolant clogging and environmentally related problems with an oil mist lubrication system. Essentially, the spindles were failing repeatedly due to plugged coolant lines, which resulted in overheated motors, and the persistent need to monitor both the coolant and mist lubrication systems consumed time and money.

Solution: The original spindle was completely replaced with an air-cooled grease-packed version. The air-cooled spindle resolved all the problems plaguing the motor coolant system and eliminated the costs for coolant tank, pump, and air oil supply. Contamination and clogging disappeared, motors no longer overheated due to clogged coolant lines, and spindle uptime increased. Additionally, the greased-packed bearings reduced lubrication failures and clogged lubricating ports, adjustment of the machine by operators was made easier without obstructions from hose lines, and environmentally related concerns about the effects of oil mist evaporated.

As such cases indicate, when complex machinery runs into problems, a single solution may not be entirely sufficient. Machinery should be viewed from a “systems” perspective and problems more often than not must be tackled on multiple fronts.

With the many possible causes of spindle failure and the depth of expertise often required to return the equipment to service, SKF repair, remanufacturing, and upgrade services have become key capabilities housed at the growing number of “SKF Solution Factories” located strategically in the USA and around the globe. These facilities effectively provide readily available physical access to a portfolio of services and competencies under one roof.

The first SKF Solution Factory in the United States opened two years ago in Houston, and the newest, 70,000-sq.-ft.dedicated site opened this month in Cleveland. Up to 40 Solution Factories are anticipated worldwide by 2016.

In addition to spindle-oriented expertise, a Solution Factory’s portfolio of competencies includes applications engineering, bearing application expertise, sealing solutions, lubrication system expertise, mechanical equipment services (such as mounting, alignment, and balancing), remote condition monitoring and diagnostics, engineering consultancy services, and operator and worker training and workshops, among others. Additional resources at the Solution Factory include customer and sales education centers

Sustaining the health and reliability of machinery is essential in today’s industrial environment. An SKF Solution Factory uniquely provides a destination where the most stubborn problems can be resolved and innovative opportunities for improved asset performance can be applied to achieve increased productivity and uptime.

Edward Zitney, Jr. is SKF Solution Factory Manager-Cleveland. He has over 30 years of experience in the repair, reconditioning, and upgrading of machine tool spindles. Contact him at 216-469-0097 or [email protected]