The developer of one telescopic clamping device now reports a new variation of the design. Mark Grizotzky writes:

“This flat telescopic clamping unit is comprised of some details that have relative movement to each other, with only one coordinate in each direction.

“The flat forms have a ground surface for smooth finish, and all components (clamp, hold-downs, core) have been processed with heat treatment for instrument-grade steel.

“The details are flat in form and have negative allowance and tensions between them, thanks to balls and separators between balls.

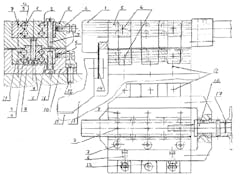

“The sketch shows that the design of the unit is simple: The clamp (1) is a flat part with a head that, with the help of the screw (16), presses the body (5) and head of the clamp (1) to a metallic tape (14) and stops the carriage (13) at the base (15).

“The body (5) together with the core (8) have movement in the plane (10) with the balls (3) and separators (4), and have negative allowance and tension.

“All movements for the clamp (1) and core (8) take place within the hold-downs (2; four pieces) with v-slides on the two sides for balls.

“Tension is created by the screws (6), and after fixture by screws (7 and 11). The body (10) is fixed on the base (15) by the screws (12.) Screw 16 has a handle (17), and the core (8) is fixed on the body (5) by screw 9 (three pieces).

“The unit is reliable, but it will need lubricating oil,” Mr. Grizotsky observed, noting that “the unit can be covered.”

About the Author

Mark Grizotsky

Owner

Mark Grizotsky, owner of MLG Tool Design in Willowdale, Ontario, has been a major contributor and influencer to machinists everywhere with his insights to machine design and set-up, tooling design and selection, and advice for preparation and processes.