Idea plugs hole problem

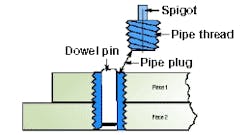

Heat treating for hardening often changes the shapes and true locations of holes in workpieces. This is especially problematic if two workpieces must be dowelpinned together. So, to provide leeway for correcting holes that don't line up, I drill and tap a pipe thread in the two parts prior to heat treating.

After heat treating, I machine a soft steel pipe plug, leaving a spigot at the top for screwing the plug into the two workpieces using vise grips. I then machine the soft plug flush (tops and bottoms) with the two workpiece surfaces, properly locate and clamp the parts together, and drill and ream for the dowel pin.

Nils Bradley

Westerly, R.I.

www.aminfo.biz/410.ad