DOE to Fund GE’s Nuclear Fuel Reprocessing Study

GE Research has drawn $6.4 million from the U.S. Dept. of Energy to study nuclear fuel-reprocessing technology. the research project is part of a DOE Advanced Research Projects Agency-Energy study aiming to increase the volume of used fuel that can be reprocessed, and to introduce new safeguards and data protection measures for those efforts.

According to GE, the program has the potential to save facility reprocessing operators hundreds of millions in costs.

GE’s lead researcher explained that fuel reprocessing operators at times must halt operations to perform a full inventory of nuclear materials within the plant. Some outages are scheduled for these physical inventory checks. The physical and digital solution GE Research is working toward would enable real-time tracking and measurements of a plant’s nuclear inventory, to minimize unplanned shutdowns and reduce the time required for planned shutdowns.

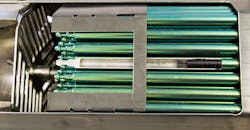

“We will introduce novel sensors, which will involve Monochromatic Assays Yielding Enhanced Reliability (MAYER) interrogation techniques, to accurately characterize and measure the used nuclear fuel throughout the reprocessing,” according to project leader Bogdan Neculaes. “This data will be transmitted continuously to GE’s AI- driven digital twin of the reprocessing facility, enabling real-time tracking and measurements of used fuel material.”

To maintain safety standards and data protocols, GE will integrate an advanced distributed ledger/blockchain technology to secure the used-fuel tracking data.

Partnering with GE Research in the project are GE Hitachi Nuclear, Sandia National Laboratories, Orano, and Lumitron Technologies.

Neculaes said that GE Research’s focus is to establish a safer, more productive, and economically viable way to recycle used fuel. “We’re aiming to develop a unique solution that would enable facility reprocessing operators to keep the tracking and measurements of used fuel flowing in the pipes of the facilities themselves,” he explained. “This has the potential to yield estimated savings in the hundreds of millions of dollars annually in operating costs, while enabling more used fuel to be recycled with enhanced safeguards.”