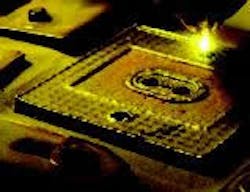

Metal deposition repairs critical parts

The LENS direct-metal-deposition system reduces repair cycles for critical parts.

Extending the life of aging aircraft, combat vehicles, artillery, and small arms for the Department of Defense (DoD) requires sophisticated repair and overhaul techniques. A costeffective solution to reduce repair cycles and provide higher-quality parts versus traditional repair methods is Optomec's Laser Engineered Net Shaping (LENS).

Developed at Sandia National Laboratories, LENS is a direct-metaldeposition system using a high-powered laser beam (cwNd:YAG) focused on a part where computer-guided metallic powder is injected to build up 3D layers, until the part repair is complete.

The LENS process produces fully dense material, which eliminates the need for heat treating for many applications. Due to the rapid solidification that occurs, superior strength and ductility is achieved for most metal alloys. The LENS process is done in an inert atmosphere that can be operated unattended for extended periods of time. The system can be used for repair, hardfacing, and 3D-part fabrication.

The system is good for components requiring repair and overhaul, such as turbine blades, vanes, impellers, stator assemblies, and rotating air seals, to extend system life due to the effects of corrosion, fatigue, and stress.

The performance and reliability of these components and assemblies are critical to ensure military assets are combat ready. For some parts, a hardfacing layer may provide an

adequate repair solution. However, other components made from difficult-to-process materials require more complicated repair processes. These repairs can involve 3D features, radial-oriented structures, and directionally solidified or single-crystal materials.