Rollers are the driving force

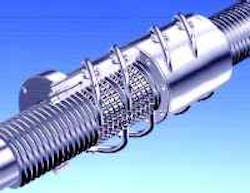

THK's Rollerscrew is reportedly the first driving element to use rollers between the shaft and nut.

UNLIKE TRADITIONAL BALLSCREWS, which use balls as the rolling element between the shaft and nut, the new Rollerscrew uses rollers. According to developer THK GmbH, Ratingen, Germany, this arrangement doubles service life and achieves high-load capability. The Rollerscrew is also equipped with THK-pioneered cage technology, which separates the rollers from one another and guides their circulation.

THK claims the Rollerscrew's high lead and DN value provide fast feedrates, and the redirection of the rollers in a tangential direction minimizes noise emissions during operation.

Rollerscrews come in five sizes with shaft diameters ranging from 2 to 4.7 in. Additional sizes will soon be available.