All gearboxes — transmission gear cases and variable feed cases — must be examined after assembling and before they are ready to be mounted on the machine tool. We need to examine them for vibration, to reduce gear noise, to locate any oil running, to evaluate the performance running light and running with load, to observe an lapping in gear, and so forth

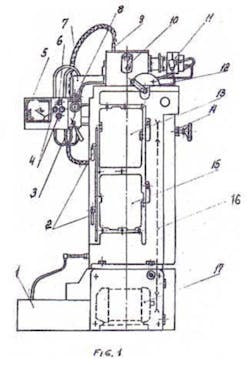

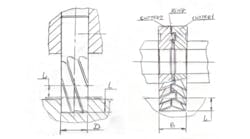

Figure 1 shows a diagram of a set-up stand for gearbox inspection.

On the housing (1) we mounted a gearbox for speed (13) and a gearbox for feed (15) by blank holders (2, four pieces) and screws and pins.

The rotation is powered by an electric motor (17), belt drive (16), and two belt pulleys. The electric motor is rated at 1.7 kW, 1420 rpm, 220/380.

On the top of housing we mounted a reductor (10) for the pump (11) and throw-over (12) for load and zero load.

The pump serves as a load that we use to open or close the gap of the throttle (3). They have separate hydraulic systems, together with an oil tank (7). Also, we have a wattmeter and device for showing oil pressure.

We need to have oil available at all times when examine is in progress.

The gearboxes are examined under load in straight direction, and in the reverse by three and two minute sequences for every step of speed and feed.

After examining the gearboxes we remove them from the stand and looking with attention to specific areas of testing, and then make some improvements if it necessary.

This stand stays in the shop and helps in the examination of gearbox speeds and feeds.