Machine tool spindles have evolved over the years into highly advanced technology solutions essential to key operations on the shop floor. Typically, they are used to rotate cutting tools, grinding wheels, or parts to be machined in applications ranging from milling, drilling, and boring to grinding, cutting, and sawing. Serving as the “heart” of a machine, spindles are engineered to deliver high levels of speed, accuracy, precision, and repeatability. Ultimately, they represent complex systems integrating dozens of components influencing machine tool performance.

As with any critical asset, however, spindles can take a “turn for the worse” and fail for any number of reasons, whether due to contaminants, loss or increase of preloads, a number of lubrication issues, improper care and maintenance, or even using an inappropriate spindle design for an application. Users can help to mitigate these and related issues by understanding how and why spindles can fail and, in the process, help keep spindles up-and-running as intended.

Common causes of spindle failure

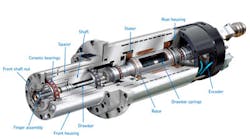

Normal fatigue wear of spindle components is a root cause of failure that can be expected over time. Spindle components typically subject to wear include the shaft; front, rear, and main housings; bearings; stator; rotor; finger assembly; drawbar springs; spacer; encoder; and front shaft nut and cap. If any of these exhibits signs of wear or damage, the component should be repaired or replaced.

Contaminants can affect shafts and/or bearing and can include any foreign substances ranging from coolant and condensation to grinding swarf, chips, and debris from material being machined. Proper seal installation and maintenance can help minimize risks.

Improper lubrication can increase wear, generate excessive heat, and result in higher-than-required operating temperatures. This can limit speed and power, while reducing energy efficiency. Supplying the right lubricant in the right amount at the right time is a “must.”

Lubricants should always be of high quality, properly specified, and stored for the application, and clean and free from moisture or other contaminants. Neither too much nor too little lubricant should be applied and lubricant containers and all transmission lines should be inspected to rule out pre-existing contaminants. In the case of air/oil lubrication systems, clean and dry air is imperative for prolonged spindle life. Lubricant additionally can be subject to breakdown in service and should be regularly monitored to confirm integrity.

Mishandling is another frequently encountered cause of breakdown. A radial or axial impact to a spindle shaft can cause brinelling, or permanent “denting,” that subsequently will result in rapid deterioration of a spindle’s precision bearings. Spindles should be properly handled and protected from vibration and other potentially adverse influences to help keep the equipment performing as intended.

In short, there is no shortage of potential causes that can result in spindle failures. Others include overloads or improper preload on bearings, imbalance, tool-change errors, improper repair, and there are many more.

Extending spindle service life

Operators can make a big difference by helping to promote good health for a spindle and extended service life.

For example, tool holders should always be properly balanced. When a tool holder assembly spins during an operation, imbalance in the spinning components creates centrifugal force – increasing exponentially with the speed. As the force increases, excessive and potentially troublesome vibration will follow and result in poor machining and difficulty in holding close tolerances. The causes of a tool holder’s imbalance may be inherent in its design; the tool holder may not have been properly balanced from the beginning; or the tool holder may have been damaged or modified by the end-user.

Calculating a “balance tolerance” can provide an acceptable range for operation. This process designates the intended operating speed and then specifies the maximum allowable imbalance within the speed parameter. Balancing within the “tolerance” range can help avoid problems and boost spindle performance and accuracy.

Vibration should be within normal parameters. Excessive or abnormal machine vibration often will indicate a spindle problem and, if this is the case, the spindle should undergo a checkup.

Operators should make every effort to protect spindles from coolant. Contamination from intense tool coolant spray or flood coolant can wash the grease or oil out from the bearings and attack the spindle’s shaft, motor, and electronics. Coolant should be directed at the tool and away from the spindle.

Monitoring the spindle’s operating temperature for fluctuations can offer an early warning sign of bad things to come. Once the normal operating temperature for an application is ascertained, it can be helpful to record baseline temperatures for the spindle’s front and rear bearings for comparison (and possible remedial action).

Other best-practice tips to help extend spindle life include: listening for unusual and/or noticeable audible noise as a potential alarm about trouble; keeping clean and proper oil flow; supplying clean and dry compressed air; and watching feeds and speeds to arrive at the perfect combination for the application.

Remanufacturing vs. replacement

Today’s economic climate helps to make a strong case for remanufacturing, or repairing, spindles when they fail. Outright replacement may sometimes be necessary, but often the desired course of action will be to get the spindle returned to service quickly and reliably. Ultimately, delivery times, costs, and productivity issues all will determine the correct route to pursue.

On average, the lead-time for delivery of a new replacement spindle can run as long as 24 weeks, while repairs or reconditioning can usually be made in less than two weeks (and, in some instances, even a few days.) The price for a new spindle, too, sometimes can average as much as triple the cost of a remanufactured unit. In addition, the investment in remanufacturing will involve only the components that need to be replaced without the higher costs associated with purchasing an entirely new spindle. Furthermore, spindles can be remanufactured many times over without adverse consequences and upgrades are always possible.

Here’s a real-world case to illustrate how spindle remanufacturing benefited one of our customers:

The shop was experiencing high failure rates with its machine tool spindles and associated losses in productivity. The customer’s “fix” was to replace the spindle bearings every time, which were noticeably compromised from ingress of coolant. But this remedy proved short-term: the spindles still would go down again every four to six weeks.

Detective work showed that the ingress of coolant (and resulting damage to the spindle’s bearings) warranted scrutiny. As part of a remanufacturing process, proactive measures were taken involving the spindle’s sealing system. Inadequate seals were removed, an air purge was added, new properly specified seals were installed front and rear, the rear cap was replaced with one that included a seal diameter, and both the shaft and front cap to accept the new seals were reworked. The result: MTBF (Mean Time Between Failure) for the spindles dramatically increased from a matter of only weeks (before remanufacturing) to 18 months – more than six times longer.

Vetting the spindle service provider

Dedicated spindle service facilities should possess in-depth knowledge to perform optimized repairs and rebuilds. They should be equipped with a wide range of in-house capabilities and support – including engineering, precision grinding, machining, and manufacturing. Knowledge and specialized experience with all spindle brands, types, and applications is essential, as well as knowledge about the universe of potential spindle defects and their root causes.

When turning over a spindle to an outside expert for remanufacturing, watch for these best-practice procedures, among others:

• Spindles should be carefully disassembled in a dedicated area to maintain quality control. Technicians should look for signs of contamination, signs of a crash, lack of oil, misuse, or other apparent signs of failure. Once a spindle is completely disassembled, each component should be polished to remove surface rust or damaged high spots.

• Disassembled spindles should be taken to an inspection area, where trained technicians can analyze each component for size, run-out, alignment, roundness, and parallelism. A subsequent detailed report can then be generated for subsequent action.

• Areas for grinding operations should be climate controlled and grinding machines should be able to grind to very precise tolerances.

• Spindles should be re-assembled in a dedicated clean room using ABEC-7 and ABEC-9 precision bearings equal to or better than the originals.

• Following re-assembly, spindles should be brought up to operating speed incrementally, in a clean-testing area. Tests will verify speed, vibration, temperature, and critical run-outs. By monitoring all critical operating parameters, spindles ultimately can be returned to original specifications (or better).

The health of a spindle will directly impact the health of a machine tool. If a spindle’s health fails, service providers demonstrating a track record of experience can become true partners by offering appropriate diagnoses and remedies for returning spindles to desired levels of performance and longevity.

Edward Zitney, Jr., oversees SKF Machine Tool Services, a business unit of SKF USA Inc. He has 29 years of experience in the repair, reconditioning, and upgrading of machine tool spindles, and is responsible for SKF’s state-of-the-art Spindle Service Center in Mentor, OH, and the recently opened SKF Solution Factory in Houston. Contact him at 800-589-5563 or [email protected]