An Ohio manufacturer has developed a device that promises to make milling a cleaner process, improving the shop atmosphere and making operations neater and safer.

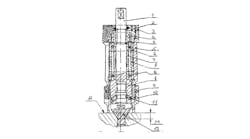

The Aerowell Table Top Milling Machine Enclosure is designed specifically for knee or turret type milling machines, according to Aaron Welch of Aerowell, in Wayne, Ohio. Welch is an experienced machinist, tool-and-die maker, tool designer, and product designer.

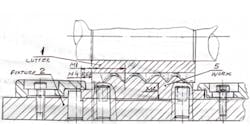

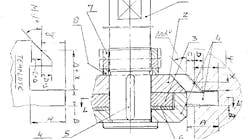

The enclosure gives a knee mill operator the ability to dry-machine or use flood coolant while keeping the machine and work area clean. The vise or other workholding device is mounted inside the enclosure’s pan.

Standard models are designed to capture chips in the enclosure, which are extracted by scooping or vacuuming. When using flood coolant, drip edges along the pan’s slots will channel coolant into the ‘T’ slots of the machine table.

The enclosure is completely modular and disassembles easily, and there is no need to remove the vise. Standard models are recommended for tool rooms, maintenance departments, labs, training facilities, personal workshops, or even job shops. Models designed to handle higher volumes of chips will be coming soon.

A short video demonstration is available online at Aerowell’s website.