A collaborative effort by Gibbs and Associates and SPRING Technologies has resulted in a significant new functionality for the GibbsCAM program: a NCSIMUL Plug-in that establishes a direct link between the machining software and the NCSIMUL NC simulation and feed-rate optimization program. After NC programs are corrected of errors and gouging, and fully verified, NCSIMUL provides options to optimize program parameters to improve toolpath cycle time and cutting tool efficiency.

SPRING Technologies’NCSIMUL SOLUTIONS is a simulation platform for production applications. It also offers PLM integration services, and it works with programming experts in the aeronautics, transportation, defense, and consumer goods markets worldwide.The NCSIMUL plug-in is available now from SPRING Technologies and its resellers.

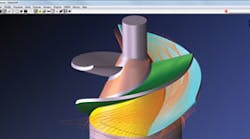

GibbsCAM is a series of CNC programs that support 2- through 5-axis milling, turning, mill/turning, multi-task simultaneous machining and wire-EDM. It also provides fully integrated manufacturing modeling capabilities, including 2D, 2.5D, 3D wireframe, surface, and solid modeling.

The standard GibbsCAM machine tool simulation works from the GibbsCAM program data before post-processing, and uses machine-tool models created by the user, However, NCSIMUL uses the machine-ready, post-processed NC program (G-code/ISO code), bringing simulation and analysis a step closer to actual machining.

It also provides an extensive library of kinematic models for lathes, turning centers, machining centers, and multi-task machines, which saves users the time required to create precise models of their own machine tools.

“For many years, our approach to complementary technology that improves customer productivity has been adoption, not reinvention,” explained Robb Weinstein, senior vice president of Sales and Strategic Planning of Gibbs and Associates, “so the integration of NCSIMULwith GibbsCAM is exciting, as it can help ourcustomers improve cycle times, tool life and surface finish with analysis and optimization at the last step before machining.”

"With this integration, we hope to help GibbsCAM users achieve higher productivity through the toolpath analysis, verification, simulation and optimization NCSIMULprovides,” stated Olivier Bellaton, general manager of SPRINGTechnologies. “For them, the NCSIMULPlug-in enables direct access to our machine-tool library, and all the functions designed to improve the accuracy and efficiency of the machining process.”

For the GibbsCAM user, the NCSIMUL plug-in is more powerful than a stand-alone application for two reasons. First, for ease-of-use and user productivity, GibbsCAM is a fully integrated application that never requires the user to leave the GibbsCAM environment to complete programming operations. To maintain this integrity, the plug-in is accessed and activated from the GibbsCAM menu bar.

Second, as a plug-in, NCSIMUL imports GibbsCAM solid models of part, stock, fixtures and other workholding devices, plus tooling parameters, to develop the 3D tools required for full and accurate simulation.