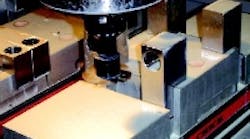

An Iscarmill slitting cutter slots all four sides of a part in one clamping on the milling machines at SR Instruments.

An awkward and extended setup hindered competitive turnaround times for a particular part at SR Instruments in Tonawanda, N.Y. The manufacturer of hospital scales and a variety of marine equipment had to flip this part three times to reach its four sides for a slotting operation. So, to reduce setup time and work stoppage, SR switched from using an endmill for the slotting operation to an Iscarmill slitting cutter.

The slitting cutter from Iscar Metals Inc. (www.iscarmetals.com) reduced the shop's previous four setups to one because it reaches the part's four sides. As a bonus, the shop also decreased process time from 354 seconds to around 100 seconds, and the slitting cutter produces 80 slots per index, as opposed to the 16 slots per index the shop was getting.

SR's Iscarmill slitting cutters feature prismatic, wedged clamping systems, which let the shop manually position each cutting insert between the flexible jaws of self-grip pockets. These pockets hold self-grip inserts and require no screws or spare parts. Stoppers located in each pocket limit the insertion of carbide inserts and flexible jaws to precisely, securely and quickly position inserts. SR uses a simple lever extractor and a plastic hammer to replace inserts in the slitting cutter, and it does this while the tool remains in the machine to further reduce downtime.

For the slotting operation, SR runs its 2.48-in.-diameter Iscarmill cutters at 529 rpm with a chip load of 0.004-in. feed per tooth. The machine table feeds at 10.782 ipm with a 0.250-in. depth of cut.