Our frequent correspondent has delivered three useful examples of fixtures, designed in the machine shop and their effects for a specific workholding task:

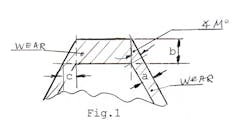

“In the first example, the fixture was designed in the shop. (See Figure 1.) The blank was made from forging steel, and the task involved machining a slot.

The blank was held, gripped in a vice on horizontal support on the milling machine. Machining was done by a milling cutter with a horizontal head. The blank was held in vertical position in a vice.

As result, there was a terrible noise from the vibration of the end of the blank, and a poor quality surface from the machining because of the vibration.

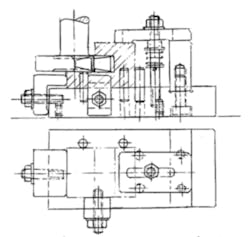

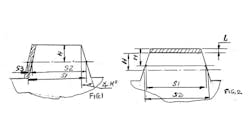

Seeing the negative result in the shop, the operator then tried to hold the blank in a vertical position (See Figure 2), using a gib clamp with bolt and nut.

The result was same that in example first.

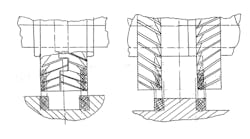

Third Example — In the third example (See Figure 3), a tool-designer offered this design for a fixture. The blank was placed on a horizontal fixture on the horizontal support of milling machine, and a vertical head was used with same milling cutter. The blank was held on the fixture with bolts and nuts.

The result: No noise due to vibration and good surface quality on the machined part — and thanks from shop.”