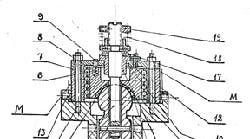

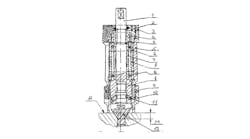

This spindle unit with an adjustable axis of rotation is the basis for coordinate measure machines, and should have very precise movement. The drawing illustrates the precision of the design:

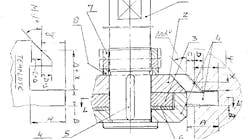

The spindle (1) has a spherical neck and mandrel (2) mounted precisely at the base of the neck, on which the mandrel’s standard measuring instruments are mounted.

The spindle rests on a spherical base (3), which is permanently attached to the lower part of the sleeve (4). Two spherical necks have two precision ball bearings (20), with separators (21).

The upper spherical neck of the spindle rests on a spherical base (5), which can move along the cage (7) sliding up and down by means of ball bearings (6) with separators. The sliding action also functions as a tightening process.

Also, the cage (7) can move along horizontal flat A of the sleeve (4) with the base (5), simultaneously as the axis of rotation is adjusted. The spring (8) and screw (9; three pieces) in the cover (10) make contact and select the gap between the spherical base (5) and spherical neck of the spindle (1) and ball bearing (20), for a tightening effect.

The screw (11) fastens the cage (7) to the sleeve (4) following adjustment of the axis of rotation, and fixed after adjustment.

Screw 13 (four pieces) effects accurate adjustment of the axis of rotation, moving it with the help of the cage (7) and base (5) using the gap (M) and establishing the most precise position for the axis of spindle 1.

Screws 12 (three pieces) prevent the case (7) from turning and the fixed base (5) after adjustment, and the screws (11) also are fixed to the case (7).

The mandrel (14) is fixed in the spindle (1) by a pin (15) that serves to rotate the spindle from the drive. The bushing (16) is a bearing for the mandrel (14).

The thrust bearing (17), spring (18), and nut (19) serve to free the spindle of its weight and that of the measuring instruments mounted on it. The unit will need lubricating, and it’s important that all ball bearings are high-precision components.