Using ceramic materials for CMM components results in a more accurate and reliable machine.

The use of ceramic material for CMM bridge and column assemblies lets CMM manufacturers ensure a high degree of thermal stability in their machine design, enhancing its measuring accuracy. The key is that ceramics exhibit a lower Coefficient of Thermal Expansion (C of E).

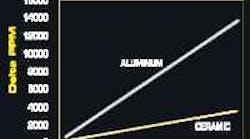

For instance, 96% alumina ceramic material has a C of E rating almost four times better than that of aluminum — 6 parts per million/degC compared to 23 for aluminum. This means that for every temperature increase of a degree Centigrade, ceramic will expand at a rate of 6 parts per million, while aluminum will expand at a rate of 23 parts per million.

As a component changes temperature, it will change in length. If the component is stress-free and the change of temperature is even across its inside and outside surfaces, as well as along its edges, the size change will occur in a linear manner. As this happens, it is possible to compensate for the linear change as long as the C of E is also accurately known.

However, this capability depends on two requirements: accurate determination of the C of E, and the homogeneity of the component material. Inexact coefficients and nonhomogeneous component materials will skew the size-change predictions. The larger the temperature change and the larger the C of E affecting a CMM component, the more dramatic and less predictable the effects of inexact coefficients and nonhomogeneous component materials will be.

Compounding the problem is the uncertainty that the C of E will in fact be accurately determined, because it varies from one batch of material to another. At best, this variation can be controlled to limits of ±10%. In the case of aluminum, that still leaves a substantial uncertainty margin of ±2.3 parts per million.

Also, be aware that temperature will not be even across an entire CMM component. Instead, the components will have a temperature gradient, along with differentials between inside and outside temperature. Moreover, in the form of castings or fabrications, the components will have internal stresses and a nonhomogeneous structure. Furthermore, components will be subject to continuously changing temperatures, making it impossible to achieve a stable condition that can be error-mapped for computer compensation.

As a result of these factors, CMM components will invariably expand in a nonlinear manner, causing the structure to bend. Because current error-mapping techniques assume linear growth, it is difficult to control the effects of thermal expansion through computer compensations. The best way to control them is to design metrology-critical CMM components with a material that combines practical weight and cost with the smallest possible C of E. Today one of the best materials available is 96% alumina ceramic.

Another advantage of the ceramic material is its stiffness-to-mass ratio, which is industry rated at 8.18 as compared to 2.52 for aluminum. The stiffer the CMM bridge or column assembly, the more repeatable the machine performance will be. In combination with the greater thermal stability of the ceramic material, these advantages result in more accurate and reliable CMM measuring performance.

Ceramics also provide an important advantage in terms of CMM guideways, which are ground and lapped to precise flatness. While ceramics can be read-ily lapped and ground, this is not the case with aluminum, which is a soft material and must first be hardened before undergoing this process. The hardening may be achieved by flame-spraying with a hardened material, or by coating the aluminum with ceramic. In either case, however, it results in a composite material with two rates of thermal expansion that can produce any number of surface distortions.