Haimer shrinking technology enhances Starrag machining centers’ precision cutting potential, delivering quality down to the finest detail for turbine blisk and blade cutting

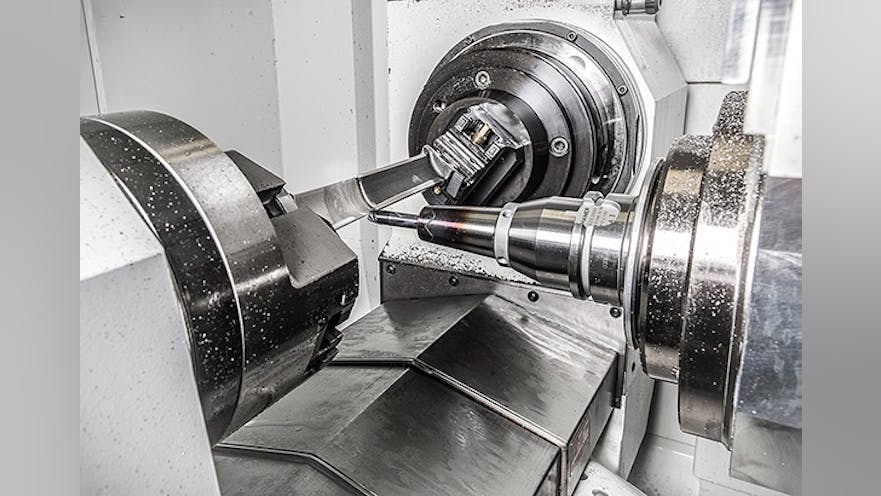

Aerospace manufacturers and suppliers have preferred Starrag machining centers for long time, in part because it offers turnkey solutions — software, clamping fixtures, tool holders and peripherals, as well as high-precision four- and five-axis cutting machines — for the critical task of producing high precision parts in hard materials like titanium alloys, as required to produce turbine blades and blisks.

At the Starrag Group headquarters in Rorschacherberg, Switzerland, the machine builder’s Center of Production Excellence (CPE) works to perfect its products’ potential for precision performance, in particular for producing highly demanding aerospace engine parts, like turbine blades, impellers, blisks and other structurally complex components.

According to Patrick Rutishauser, the group’s head of application engineering, “Technologically speaking, our machines are of premium quality. They are known for their high-performance capacity and precision. Furthermore, we offer our customers additional value regarding the application. … When a customer approaches us with a component he needs 10,000 pieces of, we design the complete system for him and supply the machine including software, clamping fixtures, tool holders as well as peripheral components and machines.”

At the CPE, Starrag engineers test and optimize demanding, and new machining processes. Rutishauser and a team of application engineers are responsible for technology and software development for “single-blade applications,” working with CAM software developers to provide machine tool operators “with exactly what they need without taking any detours or wasting time.”

The CPE is equipped with the latest four- and five-axis Starrag machines, on which the engineers test various applications, from heavy duty cutting of highly solid titanium alloy up to high speed cutting of light metal.

“We work on rotating parts, complex cubic work pieces, as well as free-formed flow surfaces – we do all of this under production conditions,” Patrik Rutishauser said. “We also produce prototype and small series for our customers. This entails developing a drawing and quality production at reasonable costs.” This means that the application specialists can acquire valuable knowledge about a machine’s requirements, and about the machining process, down to the smallest detail. “It is different from customer demonstrations where you usually overlook minor details,” Rutishauser explained.

Starrag has long understood that “tool holding” is important to high precision machining. Based on their testing of different tool holding systems, Starrag concluded it was necessary to use shrink-fit chucks, which due to their rotationally symmetric clamping body have less interfering contours and a high run-out accuracy. About 15 years ago, Starrag specialists discovered Haimer GmbH tool holding technology.

All of Haimer’s shrink-fit chucks are produced in Igenhausen, Germany, where precision-manufacturing standards can be controlled at all times. All of its chucks, even the standard ones, are made of heat-resistant steal and fine-balanced (at G2.5 at 25,000 rpm < 1 gmm unbalance). The functional surfaces are machined and ground to extremely high accuracy, and the taper tolerance is much more precise compared to the relative norm.

For special machining requirements Haimer offers special shrink-fit chucks. For example, the Power Shrink chucks are suitable for special, high-speed or high-precision milling. The patented design combines a low tendency toward vibrations with a high rigidity and a slim design on top. This special construction makes it possible for the operator to increase the cutting depth and the feed, and thus to reach a higher cutting volume while still maintaining a good surface quality.

The Heavy Duty Shrink chucks are designed especially for heavy machining with large cutting tools, and they feature a reinforced wall thickness at the clamping area, a very rigid outer contour, and patented expansion grooves in the clamping bore. High clamping forces comparable to those of milling chucks can be achieved in this way.

The portfolio of shrink-fit chucks is completed with the small Mini Shrink chucks: one-piece shrink-fit chucks with an extremely slim design and a 3-degree outer contour, designed for mold making.

“During the blade production involving extrusion profiles there are generally two procedures,” Patrik Rutishauser observed. “First, it starts with a rough cutting process, during which it is important that the chuck operates with a damping component in order to achieve a high cutting depth and feeds, and to remove as much material as possible in one production stage. “During the finishing process, however, there aren’t any strong cutting forces,” he continued. “At this point, a high run-out accuracy and the balancing quality are of importance. The Haimer Power Shrink chucks are ideally suited for both processes, and if the cutting gets even tougher we simply switch to Heavy Duty chucks.”

Starrag engineers require the very best quality for shrink-fit chucks, because during roughing and finishing machining of titanium and other hard-to-cut materials the cutting forces can be very aggressive on the interface between the machine spindle and the tool holder. “In the end, the key element is the part quality,” Rutishauser explained. “It has to be perfect starting from the very beginning, because even the titanium blanks cost a small fortune. We are convinced that the tool holder quality is absolutely essential for the part quality.”

This is especially true regarding the surface quality, which is important because the turbine blades need a very precise structure in order to achieve their intended energy efficiency. According to Starrag, it can achieve that structural precision can by milling -- and without any additional regrinding – with a surface quality of Ra=0.8 μm – 0.4 μm.

In order to shrink tools, Starrag CPE has a Power Clamp Profi Plus NG for refitting all HSS and solid-carbide tools with shank tolerance h6, and diameters from 3 to 50 mm, within a matter of seconds. It is equipped with a patented double coil technology, which means that the coil adapts itself to the length and diameter of the shrink-fit chuck. During the shrinking process only the shrinking area is heated, which reduces the heating and cooling time (via contact cooling) significantly.

In addition there is a high-end solution for professional shrinking and cooling: a Power Clamp Premium machine that offers a spacious work surface, easy handling, and linear guided cooling bodies with temperature monitoring. Starrag’s machine has an integrated length presetting – holding lengths exactly within 0.02 mm – because tools always have to be shrunk to a precisely defined overhang length.

“Haimer shrink-fit chucks are part of our standard equipment, because they offer the best conditions for process reliable cutting which people expect from us,” according to Rutishauser. “We don’t just use these products at our CPE, but we also sell them together with our own systems. … I can’t remember a single incident where a tool holder was the reason for a customer complaint.”