OKUMA AMERICA launched a next-generation addition to its horizontal machining center lineup – the Okuma MA-600HIII – with a new, 10K RPM standard spindle that effectively handles a wide range of applications, from heavy-duty to high-feed machining. The enhanced spindle is equipped with a new thru-spindle coolant suction feature, which removes residual coolant inside the tool and spindle.

This next-generation horizontal machining center weighs in at 55,000 pounds, ensuring structural stability and consistent precision machining operations for the long haul. This machine has a larger work envelope than its predecessor, with added X-axis travel capabilities.

Additionally, the MA-600HIII can perform automatic tool change operations in less than four seconds. Other enhancements have been made to Okuma’s market-leading thermal management technology, including decreased temperature deviation of the machine to an improved 7μ (seven micron) dimensional change per 24-hour period. This is particularly effective when faced with severe swings in the ambient temperature.

The Okuma MA-600HIII features an enhanced coolant-management system; ball-screw cooling for the X, Y, and Z axes; an upgraded workspace design to prevent chip accumulation; and improved chip evacuation functionality. This maximizes uptime and allows for long periods of continuous machine operation.

The all-new, sludge-less tank technology activates sophisticated filtering and liquid flow patterns of the chip / coolant mixture to mitigate settling of the mixture in the bottom of the receiving tank. This new technology reduces the need for time-consuming tank cleaning and affords increased machine operation time.

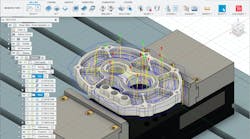

The MA-600HIII's flexible design allows for a variety of automation applications. The workspace area can equip up to seven part loading/unloading ports or up to eight workholding clamp ports, which can help eliminate the need for complicated circuit arrangements for hydraulic applications. Up to 16 ports are available in the machine's setup station, expanding part capacity and the possibilities for robotic applications.

Learn more at okuma.com/products/MA-600HIII