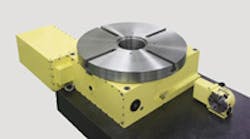

Lyndex-Nikken introduced a series of “super large, heavy-duty” rotary tables to its high-performance rotary table portfolio. Five models are available, ranging from the CNC802 with 800 mm (31.50”) faceplate capacity to the CNC2000 with 2000 mm (78.74”) faceplate capacity.

Lyndex-Nikken’s Super Large Rotary Tables are built for rigidity, with heavy-duty cast metal construction and a patented ground-carbide worm screw mechanism. This results in a balanced environment for unprecedented rigid machining. A large, dual face contact bearing support dampens aggressive machining vibrations and evenly distributes extreme loads, thus allowing the rotary tables to sustain weight loads equivalent to 22 motor vehicles (66,139 lb capacity).With RPMs ranging from 2.7 to 5.5, an indexing accuracy of 15 arc seconds, and set-up and fixturing times reduced by 90 percent, these Super Large Rotary Tables are recommended for all high-precision, high-production applications, including aerospace, construction equipment, and energy applications. Numerous rotary table sizes give multiple options to help further boost the output performance of any boring mill or gantry machining center.