Drilling holes in rotating shafts is customized via machine loading and unloading, with workpiece lengths and load-bearing capacity adjustable as required.

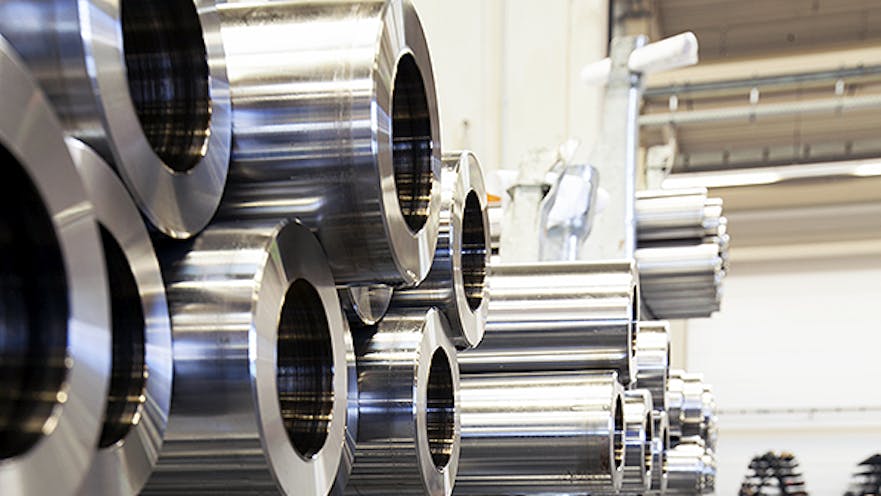

Deep-hole drilling is an important technology for any contract manufacturer processing shaft-type parts: Many shafts require relief holes, or have to be supplied with lubricant. That’s the reason Glumann Maschinenbau AG has seven deep-hole drilling machines in operation, including two supplied by TBT in Dettingen for drilling hole up to 2,000 mm deep.

The larger machine, an up-to-date ML500, is mainly used to work on various shaft configurations for a long-standing engineering customer. The diameter of the holes in these shafts can vary up to 80 mm.

The BTA/STS deep-hole drilling method is used. In this method, the cutting oil is fed to the tool under pressure along the outside of a hollow drill tube. The drill head itself, which is mounted onto the end of this tube has hard-metal (carbide) cutting plates or inserts and has openings directly behind the cutting plates that allow cuttings and cooling lubricant to exit out of the hole through the inside of the drill tubel and then into a chip conveyor.

Gerhard Glumann, chairman of the specialty contractor, noted: “As the quantity of shafts to be processed (drilled) on this machine kept increasing, we had to come with a new solution to stop us getting into delivery deadline issues.

“We opted for a fully automatic loading system, so that the machine could be operated unmanned once all processing parameters have been set,” he said. “We presented this plan to our machine manufacturer TBT, who then worked upon a solution for us”.

TBT is accustomed to developing systems for fully automatic operation of deep-hole drilling machine, many that are available as standard. But in this case, TBT designed a unit according to Glumann’s requirements and conditions.

“After inspecting the space available (at Glumann), our designers came up with the idea to arrange the components in a space-saving layout over two levels, raw parts above, and finished parts below. Each level has a conveyor chain system to bring the parts in and out,” explained Karl Heinz Napowanez, TBT sales director. On the upper level – approximately at the height of the machine spindle – there is room for about 20 unfinished parts. That’s roughly the amount processed during a usual shift. “The length of the shaft catered for can be adjusted from 500 to 2,000 mm, which means it can used for a very wide range of component lengths,” he continued.

Above the component conveyor chain, a two-armed gantry grab moves backward and forward on rails. As for the working process itself: The grab collects the raw part from the upper level, goes to the drilling spindle and puts the part into a self-centering steady rest between the three-jaw chuck and a female cone. Then it returns to the waiting position. The three-jaw chuck clamps automatically, and the drilling process can start. After drilling, the shaft is released and the grab lifts the part again from its processing position and passes it on to the lower level.

One important detail: the grab has was designed by TBT to be flexible. It covers the whole range of diameters — 80-140 mm — that Glumann needs for its customers, so it did not have to be converted.

One thing was very important for us, emphasized Gerhard Glumann: “The positioning of the loading unit behind the machine. This is different to many other automated solutions in machining technology and was necessary so that we can easily process individual orders without any difficulty by bypassing the fully automatic loading operation. This means the ML500 is accessible from the operating side like any standard machine, with no access restrictions.

The loading system is fully integrated into the machine control system. The operator only enters key data such as length of part to be processed, drilling diameter, and depth. This means the machine “knows“ the part in question and can run the NC program.

But, TBT built in other features, too: The total tool life can be set via two different workpiece counters, which trigger different reactions in the program execution. This means the machine stops for a change of cutter in good time before tool failure. The ML500 also has feed-force and coolant-pressure monitoring. If the wear on a tool should exceed a certain level more quickly, or if any other problem arises, the machine will also shut down automatically.

“Thanks to fully automatic operation, which is made possible by the loading system, we can meet the increase in volumes required without additional headcount or machine capacity,” Gerhard Glumann said.

According to TBT this type of loading and unloading is now available as a standard solution. Thanks to the flexible basic concept, workpiece lengths and load-bearing capacity can be adapted to suit individual customer requirements.