Celeritive Technologies now offers its VoluMill toolpath generating program in a “universal” version it indicates can be used with any CAM system. VoluMill Universal is a “stand-alone, ultra high-performance toolpath engine” that computes high-speed toolpath. These programs, it adds, “are cutting cycle times by up to 80 percent while doubling and even quadrupling tool life in some cases.”

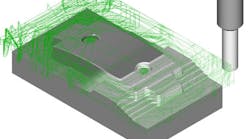

VoluMill Universal generates two- and three-axis toolpaths (shown here) for any geometric configuration, including open shapes and islands, in any format from any CAD/CAM system.

Previous releases of VoluMill were available only as fully integrated versions for Mastercam, GibbsCAM and BobCAD-CAM programs.

VoluMill Universal has the full range of functions for generating two- and three-axis toolpaths, for any geometric configuration, including open shapes and islands. It will receive part design geometry from any CAD/CAM system in any neutral format — e.g., DXF, IGES and STEP. A dialog accepts the input parameters for the toolpath and generates a toolpath program in G-code (from integrated post processing) or CL data. “Viewing and manipulation functions are second nature to NC programmers, so ultra high-performance toolpaths can be generated within minutes of installing the software,” according to the developer.

| Start your engines: VoluMill Universal is a stand-alone version of the toolpath engine previously available only for speific CAM programs. However, it has the full range of functions and capabilities as prior releases, including:

|