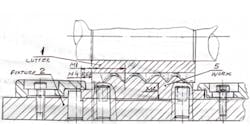

While rebuilding a small machine tool, I needed to generate a bearing surface on the machine’s bed and underneath its table. However, the way surface was degreed, and hand scraping was difficult to do around the straight column. Space was small and restricted.

I started to use an old modified file, but was not satisfied with the results. I lacked the control necessary to precisely repeat the engraving marks. What finally worked was a Dremel rotary grinding tool, two cut-off disks and a lot of practice.

I practiced making a fish-scale-type pattern on a piece of tool steel prior to actually working on the machine ways. After achieving a consistently good pattern, I checked the scalloped engraved deviation, and it ranged from 0.0002 in. to 0.001-in. deep.

Once I completed both mating surfaces on the machine, I honed off the high burrs and fitted the two surfaces together. The result was a smooth, frictionless contact surface with an oil bearing.

In addition, I discovered a simple way to frost. I mark off my directions using a black liner. The marks I make are 45 degrees opposed to one another, which allows me to frost and generate a symmetrical geometrical pattern.

Online name:

360 degree gearhead

Bellingham, Wa