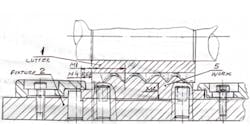

I cut four equally spaced 1/16-in.-wide slots in over two dozen 0.625-in. O.D. 0.437-in.-I.D. electrical connectors using a special setup. This 6-in.-long part had an I.D. depth of 5 in., and slot depths ran to the part I.D.

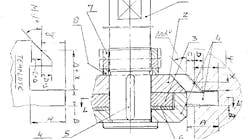

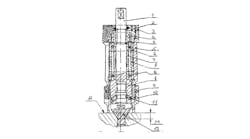

To support the workpiece, I used a 1-in.-diameter piece of aluminum turned to match the part's I.D. (slip fit) and O.D. with clearance for a slotting cutter. Its opposite end has flats for a standard mill vise. The other end of the part rests in an indexing fixture.

I then machined a holder extension out of 5/8-in.-diameter drill rod to accept a carbide grooving tool. A capscrew at the end of the extension secures the grooving tool.

After machining slots on one workpiece, I deburr it, push it through the indexing fixture, and reverse the process to load the next one.

Nils G. Bradley

Westerly, R.I.