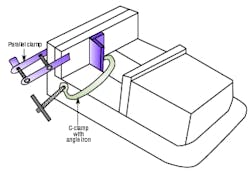

Quick workstop

For a quick workstop when the part and setup allows, I use either a parallel clamp or C-clamp with a short piece of angle iron, if possible. These stops take less than 20 sec to set up and are sturdy enough for those machine operators who are a bit rough when loading workpieces. The clamps also seat below the workpiece's surface, thus eliminating interference.

Joseph Snyder

Jackson, N.J.

Workholding from the fridge

Lathe chucks can leave marks on workpieces. To keep this from happening, most shops lay small pieces of soft copper or aluminum on the jaws. Unfortunately, the task sometimes requires a third hand to hold the pieces in place, and even with assistance, the pieces inevitably fall into the machine's chip pan before the chuck is tightened.

My idea is simple and involves refrigerator magnets. I cut 0.750-in.-wide strips about 1-in. long out of the magnets popular with local pizza places and politicians. The magnetic material's backing readily sticks to chuck jaws, and its front is usually soft enough to protect workpieces.

Charles Neil Richardson

N. Syracuse, N.Y.