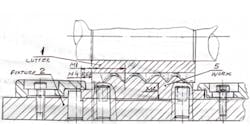

The cut off piece of hex key must be square to use as a broach.

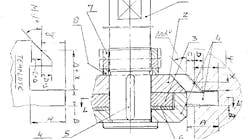

Run the hex-key broach into the workpiece to produce a hexsocket pattern.

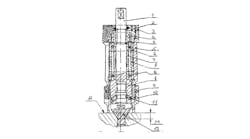

A finished lefthand 1/4-20 screw with custom head made using the special broach idea.

My idea is for easily producing custom, hex-head socket screws. The quick procedure is coldworking, so it generates sockets harder than those produced by EDMing.

First, I cut off a 1-in.-long section from the straight end of a hex key, making sure the cut surface is square because the piece needs to work as a broach. Then I mount a drill the size of the hex key's major diameter in a lathe's headstock chuck and clamp a piece of steel (approximately 1/2-in.-thick) in a toolholder secured on the machine's toolpost. By moving the piece of steel into the drill using the lathe carriage, I drill a hole for guiding the broach.

Finally, I load rod stock in the machine chuck and drill — with a bit matching the hex key's flat-to-flat distance — to a depth of 11/2 the drill's diameter. With the short piece of hex key in the guide hole, I hammer it into the workpiece until it reaches the bottom of the hole, thus producing the hex pattern.

The broach is removed with a pair of visegrips and a few light taps. For the finishing touch, I chamfer the hex socket's entrance using a countersinking tool.

Charles Todd

Cedar Park, Tex.

Tapping into a storage problem

Storing loose taps together in a drawer or box is messy, unsightly, and inefficient. Adding to the problem, size markings etched on taps, especially small ones, are difficult to read when searching for a particular size in a cluster of many others. To remedy this, I use end mill tubes.

Instead of discarding these tubes, I store same-size taps in them. These tubes are usually square-shaped, so it is easy to mark tap sizes on them and neatly line them up according to size in one's toolbox for quick retrieval.

Frederick Lorenzen

Wantagh, N.Y.

Pick the winning Practical Idea!

Select the best Practical Idea in this issue by circling the associated number on the reader service card. Winners receive an award of $100. An honorarium is paid for each item published in this column. Submitted ideas are subject to editing, and sketches will be drawn to conform to AM's style and format. Submission of clear, close-up photos is encouraged.

Send material to Practical Ideas, AMERICANMACHINIST, Penton Media Inc., 1300 E. 9th St., Cleveland, OH 44114-1503. Please include your name, address, zip code, and Social Security number.

Winner for October 2004: Richard Kurdyla, "Cleaning gundrills," p. 60.