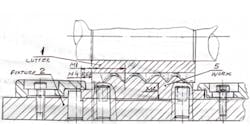

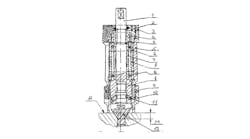

Roughing spline shaft hobs with 2-radius teeth profiles are used to generate rough straightside spline shafts, leaving extremely uniform grinding stock allowances distributed on the I.D. of the shaft and close to parallel to the width spline sides on the shafts.

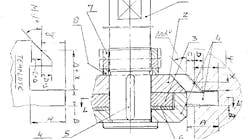

My idea is for eliminating the difficult radii at the sides of teeth profiles of a roughing hob and substituting them for broken lines from both sides of the teeth. To do this, I developed a computer program in which “M” represents an equal straight line inscribed on the tooth’s radius profile. M can be 1, 2, or 3.

When M is 1, it means joining two points bottom and top intersection radius with the bottom cutting edge and top cutting edge of the tooth from every side. The result looks like a trapezoidal tooth profile – trapezoid with two straight lines.

When M is 2, there is an arc radius. Two equal lines are inscribed from each side of the tooth. It will look like an obtuse angled triangle on each side on the chord radius arc of the tooth.

If M is 3 in an arc radius, three equally straight lines run from each side of the tooth, resembling a small trapezoid. The tooth’s cutting edge will look like a big trapezoid with two smaller ones from each side.

At the intersections of all these lines, there are small 0.005-in. radii. In addition, my program indicates all angles of profiles and intersecting points for vertical axes where angles start. These angles are dependent on the number of splines and not on the diameter of the shaft, but every shaft diameter and number of splines determines the required roughing hob.

Once decided upon, profile angles are easily ground and relieved on a grinder. They should then be checked using an optical comparator.

Mark Grizotsky

Ontario, Canada