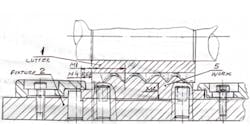

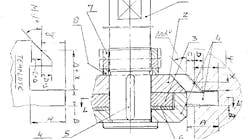

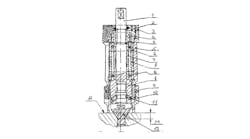

Several spherical-shaped mold inserts with varying radii around 1 in. in 0.010-in. increments presented us with a machining challenge. A lathe wouldn't work, so we did the job on a CNC milling machine equipped with an old lathe headstock.

After mounting the headstock on the two-axis miller, we fabricated a drive system and made a lathe toolholder that fastened to the machine's quill. We basically CNC lathe-turned the parts using carbide inserts. The inserts' nose radii provided tool offsets. Total time from concept to finished parts was one 8-hr day.

John Greene and Steve Earle

Plymton, Mass.