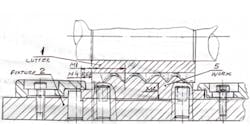

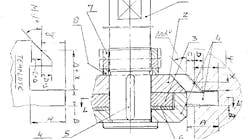

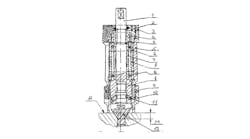

After milling 0.866-in. (22-mm)-wide slots in stainless steel parts, I spent 3 hours polishing the internal surfaces of each slot, including their radiused depths, to achieve a required Rz 5 µm finish. To reduce the polishing time down to 30 minutes, I mount a grinding wheel in a milling arbor on a vertical machining center and grind the slots after leaving 0.002 in. (0.05 mm) of stock from the slot-milling operation. I also attach a fixed single-point wheeldressing tool to the machining center's table for programmed wheel dressing.

P. Anandaraj

Coimbatore, South India