When machining Inconel 718, for example, the company said speeds can be increased four to five times compared with cutting speeds when using carbide inserts. The inserts are equally productive in the automotive industry, machining alloyed gray cast-iron brake disks, and in the roll products segment removing casting crust or heavily worn rolling surfaces.

KY4300 inserts are composed of aluminum oxide reinforced with silicon carbide whiskers. These whiskers have high mechanical strength and act like reinforcing steel bars in concrete, improving the strength and fracture toughness of the cutting insert.

Salah Taoufik, Kennametal’s global product manager for turning, said KY4300 tools have excellent high-temperature strength and hardness, and speeds can be increased 10 percent to 20 percent in most applications, compared with other ceramic grades, and produce results that include better surface finishes at lower cutting forces.

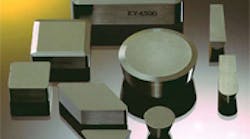

When it comes to machining hard, difficult-to-machine materials, it’s tough to beat poly-crystalline diamond (PCD), cubic boron nitride (CBN) or ceramic inserts.

PCD is a matrix of randomly arranged diamond crystals that are bonded to form an extremely hard film or wafer.

These tools effectively machine highly abrasive, non-ferrous materials, including graphite, highsilicon aluminum alloys, fiberreinforced synthetics and copper alloys.

CBN is the hardest known substance next to diamond, and provides the cutting edge for long-lasting tools that proficiently machine hard steels to 66Rc, as well as hard castings, Inconel, Monel and Stellite.

Ceramic inserts can run at high speeds, so they reduce machining times. They resist oxidation and maintain hardness at elevated temperature, and are ideal for hard machining carbon steels, alloy steels, tool steels and cast irons.

Emuge Corp. (www.emuge.com) has announced the expansion of its hard milling end mill line to include new PCD and CBN end mills.

The tools are pre-engineered and precision manufactured for optimum performance for cutting challenging cutting applications. The PCD shaped cutting edges are affixed to carbide shanks by a sophisticated microwavebrazing technique that forms bonds that are able to withstand temperatures to 1,100° F.

The company said the end mills are extremely durable and can provide 50 times more tool life than conventional carbide end mills. Emuge PCD and CBN end mills are available from stock, in ball nose, torus and flat-end designs, in sizes from 0.1857 in. to 0.500 in. and in metric sizes from 4 mm to 12 mm.

| Coatings without cracks When developing aluminum oxide (Al2O3) coating materials, it is preferable to use the alpha form of for most applications. Unfortunately, it is much easier to deposit the kappa form. Consequently, producers have deposited the kappa form and then heat-treated it in a coating furnace to transform it to alpha. However, this heating process results in an unavoidable contraction in volume, resulting in the formation of cracks in the coating. About three years ago, Seco Tools Inc. (www.secotools.com) metallurgists hypothesized that if they could directly deposit the alpha form in the beginning, they could avoid the cracking issue and produce a more homogenous and tougher structure. Eliminating cracks would also make the coating a more effective thermal barrier, reducing the amount of heat getting to the substrate. |