Switching vises shortens cycle times

At Precise Products, a high-density manual-model Kurt vise holds four, instead of two, aircraft-sensor component parts, reducing cycle time by 25%.

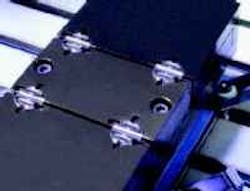

Improving an existing machining center's productivity took nothing more than changing vises at Precise Products Corp. in Minneapolis. The shop switched to a high-density manual-model vise that holds four parts and reduces cycle times per part 25% for aircraft-sensor components made from 410 stainless steel blanks.

Before purchasing its HDM6AL manual vise from Kurt, Precise considered several other alternatives, including faster machining centers equipped with double-station vises or cluster-tower setups. However, after some investigation, the shop realized the potential cycle time reduction in a 4-part setup as opposed to its former 2-part one.

"The travel distance from part to part is small, so less machining time is lost when the cutting tool travels between parts," explains Steve Gourley, manufacturing engineer at Precise. "Machining four instead of two parts cuts setup time more than half, and the new vise sets up much faster than our older, standard vises. Also, operators now have more free time between setups to check each finished part and tend other nearby machines."

The HDM6AL vise's 13.75-in. length and 6-in. width expedite reduced cycle times while maintaining part quality at Precise. The vise is smaller than previous models, so the machine spindle travels less from part to part and to get into and around each for machining. It clamps parts with a force of 5,556 lb and 70 ft/lb of input torque while providing repeatable accuracy to 0.001 in.

By machining the HDM6AL's 7075-T6 aluminum jaws to hold the outer contours of four parts per setup, Precise's machine operators, in effect, create a custom fixture out of the standard vise. Parts nest inside the jaws, held tightly, so there's no chance of part misalignment or chatter at high speeds. The jaws are also quickly replaced for different jobs.

Kurt Manufacturing Co.

Minneapolis

kurtworkholding.com