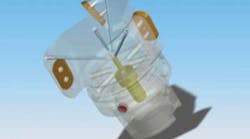

The bar feeders can be customized for any size or shape bar stock by changing the feed tube. They are available with tube sizes ranging from 0.25 in. to 2.75 in. in 0.125-in. increments, accommodating bar stock diameters from 0.125 in. to 2.75 in., and up to 12-ft long. Four userspecified feed tube sizes are standard, and customized tube sizes are available. Oil fills the gap between the bar stock and feed tube, acting as a noisedamping support. As the bar begins to turn, hydrodynamic forces move it toward the center of the feed tube Centering forces increase as bar speeds increase. Oil flow and pressure are controlled with a single valve. The bar feeder's front swing-out mechanism includes a large barrel clamp to reduce bar vibration. Ergonomically placed controls and a safety interlock switch facilitate system operation. An end-of-bar signal and auto pusher retraction allows for unattended operation.

Rhinobar bar feeders from Lexair Inc. (www.lexairinc.com) are designed for use with all types of CNC lathes and for dedicated production jobs. The bar feeders are larger versions of the company's Mini Rhinobar, and are equipped with pedestal and barrel clamps that prevent whip or spin of the bar. Lexair says the pedestal and barrel clamps also make the bar feeders easy to install and use.