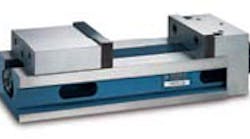

All sides of the vises are machined accurate to 0.001 in. for precise and easy alignment in multiples. They can be used as receivers for other workholding devices. Also, two XL vises can be mounted back-to-back and used vertically in a tombstone machine setup.

Kurt XL vises have 6-in. and 8-in. jaw widths with jaw openings to 21 in. (28.765 in. with jaws set in outside positions for the 8-in. model). A reverse model is available that minimizes reachover distance making large-part loading easier for the operator. Available in manual, air and hydraulic XL models, the air (6-in. model only) and hydraulic versions have a 0.125-in. stroke. For delicate parts, the air-power model provides a precise and repeatable gentle holding touch.

The XL vises feature the Anglock system, a pull-type jaw-clamping design that reduces stationary jaw deflection by at least 80 percent. The design prevents parts from lifting upward under heavy clamping loads. A hardened spherical segment mechanism produces all-directional alignment of the jaw components and vise body so clamped parts remain stationary for accurate machining.