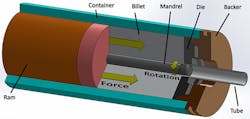

The Lightweight Innovations for Tomorrow program is undertaking an industrial research and development effort to evaluate “friction stir extrusion” for manufacturing auto body frames. Like “friction stir welding,” from which the new process draws its name, friction stir extrusion (FSE) technology centers on a rotating, non-consumable tool that stirs material in a container, heating it by friction and forming a tube as it forces the material against the hollow die form.

According to sources, FSE avoids the problems of intermetallic compounds and tool wear, and it leads to a mechanically bound joint whose strength is determined by the mechanical bond between the steel and the extruded aluminum.

“The results of this project will have a major impact on the commercial and military transportation industry,” according to LIFT’s chief technology officer Alan Taub. “By reducing the weight and cost of materials used in auto frame production, land-based vehicles will be able to operate more efficiently.”

Extruded aluminum can be used to form automotive structures, but the process can be costly and presents some challenges to maintaining microstructural control in the material. Hydroforming and welding fabrication are other options.

LIFT is a public-private partnership launched in 2014 under the aegis of the U.S. Department of Defense to coordinate industrial and academic interests to develop and deploy manufacturing technologies for lightweight metal products. It has initiated development programs with numerous manufacturers and university research centers on process technologies and lightweight product development, for automotive and aerospace applications.

In the new project the leading partner is Lockheed Martin, with Comau, and Manufacturing Technology Inc. The research partners include the University of Notre Dame, University of Michigan, University of Tennessee-Knoxville, the Ohio State University, Southwest Research Institute, and Oakridge National Laboratory.

The project will have two phases, the first to demonstrate friction stir extruded tubing has improved corrosion-resistant properties over conventionally extruded tubing; and the second to show that friction stir extruded tubing can be “representative of a production part” for a commercial vehicle.

LIFT’s new project is targeted for completion in the fall of 2018.