Mr. Mark Grizotsky contributes the following proposal for producing a specific type of roughing hob.

“This type of spline is produced on a universal gear-milling machine or special spline milling machine using a special tool that looks like a worm, and called a hob, which is familiar to tool designers.

Roughing a straight-sided spline requires a rectangular form that has a size the same as the finish size (by drawing), plus allowance for grinding two sides. After heat treatment, the allowances are grinded to the finish of spline straight size by drawing.

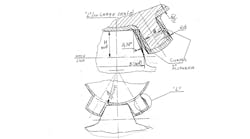

“The tooth of this hob for rough milling a rectangular-form spline looks like a trapezium, with two (involute) curves on the sides. The calculations for this shape are complicated, and the involutes are substituted on part of a circle with a radius and coordinates X and Y.

“Calculation for the circle is difficult also, and producing this hob and grinding form teeth with a template is too complicated.

“In that time we can make the milling or hobbing roughing spline by roughing hob teeth using only a trapezoidal form, with two straight lines under two equal angles.

“After hobbing, we have a roughing form of the spline teeth that looks like a rectangle with two curves (involutes) on the two sides, which provide sufficient grinding allowance, uniformly distributed on the spline sides.

"We understand that the angle of trapezium plays a main role in this calculation, and present below is an empirical formula, MLG-1. For tool-designers who know this tool instrument, and work with them every day, all data and small formulas can be found in books for designing these hobs."

FORMULA MLG-1

|

Angle M (degree of trapezium) of tooth of the roughing hob |

= |

Arc tan [(1/2xH) x (S + B/cos 3.14158/Z - (tan 3.14158/Z)xd)] |

H -- is the profile depth from pitch line of rough.hob

S -- is the hob tooth thickness on the pitch line of rough. hob.

B-- is the thickness of the spline - finish size.

d -- is roughing inside diameter with allowance rough. spline shaft.

Z -- is number of spline shafts.

G – grinding allowance.