ESPRIT 2015 generates more efficient toolpaths, adds CNC programming options

A new version of the ESPRIT CAM program will increase productivity for a range of machining applications by generating more efficient toolpaths, and save production time by providing substantial improvements in CNC programming productivity. That’s the message from DP Technology Corp. on the release ESPRIT 2015, the latest version of its flagship programming software.

Besides increasing productivity, the new release also provides several new features and improvements to established functions, specifically in the areas of intelligent machining, strategic machining, CAD-CAM data exchange, and Cloud-Enabled CAM.

Intelligent Machining — Intelligent machining features in ESPRIT 2015 accelerate the machining process by providing new five-axis cycles that reduce cycle time. This makes it possible to machine blades completely in a single setup, the developer claims.

ESPRIT’s five-axis Blade Roughing tool motion is morphed across the blade from any size stock shape to offset stock allowance uniformly, so it can be followed immediately by a finishing cycle.

“ESPRIT 2015 offers unique features in five-axis to make complex machining more efficient, allowing users to have more tool path options with features like blade roughing and chamfering,” observed Cedric Simard, global marketing and communication director of DP Technology. “ESPRIT 2015 blade roughing enables users to remove material down to uniform stock around the blade and eliminates the need to follow semi-finish cycles. Users in the aerospace, energy, medical and automotive industries will benefit the most from these time-saving operations for precision parts.”

Another intelligent machining improvement in ESPRIT 2015 is Port Roughing, a new five-axis cycle that creates a roughing operation to remove the material inside an area where the tool must enter through a restricted opening. The shape of the toolpath is an offset of the port surfaces, starting at the surface and proceeding inward at a constant stepover.

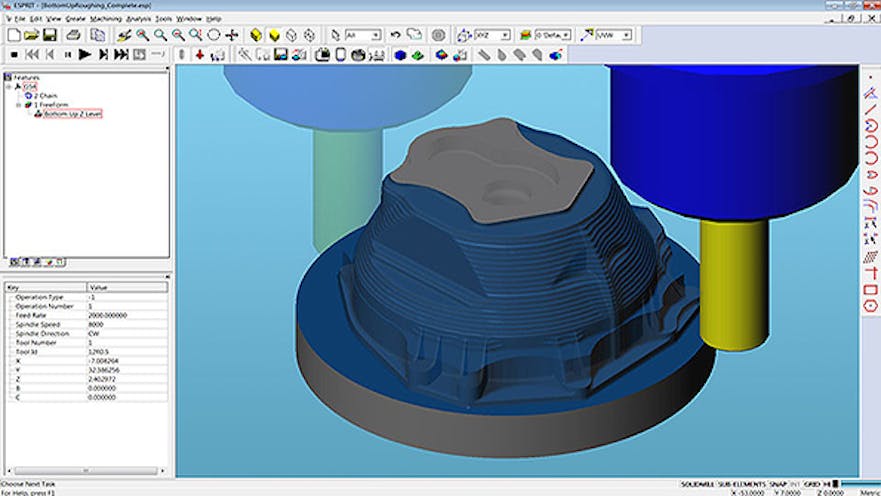

Productivity Boost — ESPRIT 2015 also includes features that increase machining productivity. The new Bottom Up roughing strategy that lets programmers attain a small residual stock height during the stock removal process. Even more, it can be combined with ProfitMilling – a high-speed machining roughing technology – for an improvement in overall productivity. ProfitMilling optimizes toolpaths with engagement angle, chip load, lateral cutter force, and material removal rate to reduce cycle time and increase tool life significantly.

Strategic machining — The strategic machining capabilities of ESPRIT 2015 have been expanded with completely redesigned stock automation capabilities for multi-tasking machines with mill, turn and drill capabilities. Available for the Facing, Contouring and Pocketing milling cycles, the new stock automation function maintains awareness of the stock removed by previous operations to generate cutting passes only in areas where stock remains. This function greatly reduces air cutting which in turn drastically reduces cycle time.

Additional strategic machining improvements have been made by providing support for slot mill tools in the Port Milling and Composite cycles. Slot mill tools save machining time on operations like tee-slotting and square shoulder milling, and their geometry generates lower cutting forces in soft materials and unstable setups which increases tool life. Barrel-shaped cutters are now supported in five-axis Blade and Composite cycles. Barrel-shaped cutters provide a much better surface finish than ball end mills because their geometry provides a larger effective radius of engagement, resulting in smaller cusps between toolpaths.

CAD to CAM — New data exchange features in ESPRIT 2015 make it easier to move information from a CAD system into the CAM environment. Three new geometry types — sketches, feature profiles and curves — are available now through ESPRIT FX data exchange from Dassault Systémes CATIA, Parametric Technology Pro/ENGINEER, and Siemens NX/UG. The additional information obtained from these geometry types can be manipulated to cover complex areas for roughing operations, or to extend surfaces to get a better finish on edges.

ESPRIT 2015 provides another important improvement to shorten programming time by increasing the accuracy of automated feature recognition. The enhanced Auto Chain support for solid faces, loops, and edges lets you create chain features directly on solid models. In addition, a redesigned wall feature recognition command automatically recognizes the upper and lower limits of walls, even tapered walls, in a solid model.

Cloud-Enabled CAM — ESPRIT 2015 allows machine programmers to select tools based on the part features in minutes — saving task of flipping through catalogs to find ideal tooling. With the ESPRIT MachiningCloud Connection, programmers have access to complete and up-to-date tooling product data, cutting hours of programming time by eliminating manual tool creation.