Verisurf Software Inc. is introducing a “revolutionary approach” to inspection automation with Verisurf Automate — a CMM programming software that makes operating a coordinate-measuring machine system faster and easier. It also offers cost-saving opportunities in the inspection processes, as a 3D CAD measurement platform that automates all types and brands of CMMs with an intuitive 3D experience, graphical object oriented programming and open standards that broaden the program and extension options.

The new platform will have a general release this month, and will be demonstrated at IMTS 2014 in September. Verisurf Software Inc. develops 3D measurement programs for advanced computer-aided surface analysis, inspection, tool building, assembly guidance and reverse engineering.

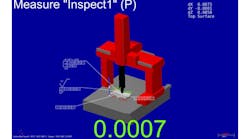

Verisurf Automate is graphical object-oriented sequencing and CMM probe path generation software that creates automated inspection plans quickly and easily; executes them, and generates reports. It has intelligent sequence tree objects that support drag-and-drop re-ordering, and are easily edited with logical right click options. Probe points and paths can be created and edited dynamically on CAD features or surfaces including specialized routines for helical and radial features. The software constantly maintains associativity between sequence tree objects and their corresponding 3D graphics display objects such as CAD model features, probe points, and probe paths.

According to the developer, Verisurf Automate will make users more productive with a 3D environment that includes an object-oriented operations manager, CAD feature extraction, and solid model associativity. Ease of use and user productivity are enhanced with file recognition, logical right mouse click options, customizable user configurations and drag and drop operations reordering. Attention to the intuitive 3D experience helps users learn more quickly, program a CMM faster, and automate CMM operation.

Verisurf Automate is a complete coordinate measurement CAD system with 3D surface and solid modeling, traditional 2D drafting, and 3D model associative GD&T. Verisurf accepts any CAD model from your customers including; ACIS, AutoCAD, IGES, Inventor, KeyCreator, Mastercam, Parasolid, Rhino, Solid Edge, SolidWorks, SpaceClaim, STEP, STL, and VDA. Optional CAD formats include; CATIA with FTA, Siemens NX, and Pro/E.

Also, Automate can create CMM inspection plans to standard STL files to automate inspection of 3D-printed prototypes and additive-manufactured parts.

CMM inspection plans created in Automate are compatible with all brands and models of portable CMM arms, scanners, laser trackers, and optical trackers and programmable stationary CMM. The same measurement plan used to run a programmable CMM can be used with a portable arm. Whether the measurement job is on the shop floor or in the QA lab this high level of interoperability empowers the technician to choose the ideal measurement device for the job.

Verisurf Automate complies to current and emerging non-proprietary, open standards, including: DMIS and I++ DME Protocol for CMM communication supported by the NIST, Renishaw and European automotive manufacturers Daimler, Audi, BMW, Opel, Volkswagen, Porsche, Volvo. Verisurf supports I++ DME to empower quality managers with inspection plan interoperability and freedom to inspect their parts with any brand or model of CMM and ultimately reduce recurring maintenance, training and support costs.

Automate extends Verisurf’s open 3D measurement platform strategy with inspection plans that can be executed on any supported stationary or portable CMM increasing flexibility, eliminating inspection bottlenecks and reducing training and support costs.