GROB SYSTEMS INC. introduced a new, compact GRC-R12 Robot Cell that offers flexible, customizable, and affordable automation for the GROB G150 five-axis universal machining center, the smallest horizontal machining center in its modular G-series Universal line. The introduction of the GRC-R12 robot cell broadens GROB’s range of automation solutions for creating flexible manufacturing cells.

“Our customers see a big advantage in having the automation and machining center come from the same builder because it enables a better support model to keep the cell running at high efficiency long-term,” stated Grob Systems’ Derek Schroeder. “Due to its flexible configuration options, we can design the compact cell to meet unique customer needs, making it possible to produce a wide variety of parts and processes on one system. Also, we prioritized minimizing the cell’s footprint to save valuable floor space.”

The cell has a 6-axis FANUC M-10iD/12 robot with 4.7-ft (1,441-mm) reach, capable of handling a maximum load of 26.5 lbs. (12 kg). The GRC-R12 features a pneumatic single-or double-gripper system.

The drawer feed system can have up to six drawers that can be unloaded and reloaded while the robot cell and machining center are in operation.

With GROB’s machine design, chip control inside the machining center allows for long periods of unmanned operation without faults. Offering high customizability, customers may select from capabilities such as a blowoff box, SPC drawer and an alignment station.

The compact GRC-R12 base unit that holds the robot cell has dimensions of approximately 5x5 ft. (1600x1600 mm), facilitating fast delivery and installation. When the robot cell is fully set up with the G150 machining center including monitors and accessories, overall space dimensions are approximately 24 ft (7,400 mm) long x 10 ft (3,250 mm) wide.

The GRC-R12 robot cell features a side access door that provides ample and ergonomical access to the G150 machine for new jobs, fixture changes, and maintenance, with a window that provides good visibility to the machine.

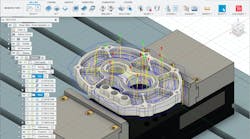

For ease of operation, integrated software enables intuitive cell control.

Learn more at www.grobgroup.com