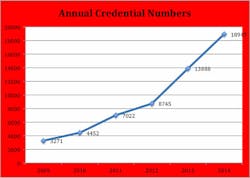

The National Institute for Metalworking Skills (NIMS) reports it awarded a new record number of credentials during 2014 to individuals seeking new or more demanding industrial jobs. The total number of credentials, 18,947, represents a 36% increase from 2013.

It is the second consecutive year that NIMS has set such a record, after issuing issued 13,888 industry-recognized credentials in 2013, which improved on the 2012 figure by 58.8%.

NIMS certifies individuals’ skills against national standards via credentials that companies can use to recruit, hire, place, and promote individual workers. Training programs in metalforming or machining incorporate those credentials as performance or completion measures to secondary and post-secondary level academic coursework.

NIMS was formed in 1995 by metalworking trade associations to set skills standards for the industry, certify individual skills against the standards, and accredit training programs that meet NIMS quality requirements. These skill standards range from entry-level to master-level across the range of metalforming and machining operations.

The shortage of qualified workers skilled at machining, programming, quality control, and other related manufacturing functions has been a frequent concern of employers, and the problem also has drawn attention from government and other economic leaders, seeking an approach to address long-standing unemployment problems, as well as competition issues.

More than 6,000 metalworking companies and major industry trade associations have invested more than $7.5 million in private funds to develop NIMS standards and credentials that prepare and advance the industry’s workforce, and continue to upgrade and maintain the standards as the industry changes.

“The precision manufacturing industry is constantly evolving, becoming more complex, technology-driven and innovative,” observed NIMS chairman Greg Chambers. Chambers also is director of compliance for Oberg Industries Inc., a manufacturer of precisions components for aerospace, defense, tooling, and other industrial sectors.

“NIMS ensures that companies, workers, and students keep up with changing industry standards and job requirements and that training programs equip individuals with the knowledge, skills, and abilities they need to succeed in in-demand jobs,” he continued.

According to NIMS executive director Jim Wall, “It is clear that the precision manufacturing sector is strong and growing, and more students and workers are preparing for success in the wide variety of jobs our industry offers.”