GE Fanuc has developed a series of aftermarket services that the company said can deliver as much as 25 percent more machining capacity without buying new equipment.

GE Fanuc’s Engineered Solutions (www.gefanuc.com) business unit has developed a method to optimize machine tool processes that includes adjusting the functions on machine tools to ensure they operate accurately and that they deliver the correct information to the machine controller.

GE Fanuc Engineered Solutions aftermarket services tune-up such machine functions as feed-forward, look-ahead, contouring controls, NURBS interpolation, and feedrate and adaptive controls.

Tuning such functions on a machine tool can extend a machine’s capabilities, Gary Highley, manager of Engineered Solutions for GE Fanuc, said.

“Users often don’t understand the full capabilities of their CNC machines. There are literally hundreds of tools in the CNC that can be used to improve productivity of the machining process,” Highley said.

“Machine tool builders provide the best value CNC system to meet their machine specifications, but may not take advantage of some key advanced features unless specified by the end user. Awareness of this functionality can lead to huge improvements in manufacturing processes,” Highley added.

For example: A machine tool’s servo system may not be properly adjusted and optimized for manufacturing, he said. Servo motors are responsible for moving spindles and tables on machines, and parts will be made out of tolerance or nearly out of tolerance if they do not function properly.

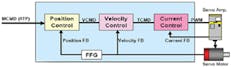

To get the best performance from a machine tool, GE Fanuc tests and adjusts servo system parameters while monitoring the machine to ensure that the responses from the servo system match the mechanics of the machine.

In addition, current loops are adjusted to high settings to realize a high response rate, and velocity loop and position gain also are set high to get higher responses to commands and to suppress disturbance torque.

Highley has a long list of other adjustments, tests and checks that he does on a machine, but he said the current loops are the heart of the servo system.

“Faster current loops equal faster response to disturbances and reduced path error. A fast current loop allows for a fast velocity and position loop. Faster loops improve speed and accuracy,” he said. A high velocity loop improves a machine’s speed of response to commands, while position gain determines how fast the servo system reacts to position deviation. A high position gain helps to reduce errors as long as stability is maintained.

Highley said basic servo tuning on a machine run by an aerospace parts producer improved the cycle time and the part profile. Cycle time was reduced by tuning the velocity and position loops for higher speeds, and by reducing acceleration/deceleration times to 150 ms from 600 ms. Part accuracy was improved by reducing path errors and interpolation errors.

In a second example, Highley said another aerospace parts producer was able to save $150,000 in the production of one part as a result of servo tuning and machine optimization on a line of seven horizontal machining centers.

The shop could not hold tolerances on the part, even while machining at 72 ipm, and had to make significant edits to its part programs each time it ran the part. Also, a separate, edited program was needed for each part on each machine, and the edited programs were based on test cuts that were done each time a new batch of parts was run.

The machine optimization included correcting settings for pulses per revolution of the spindle, which is a feedback response to the CNC; adjusting gains on the machines and correcting high precision contour control parameters.

“The result is that the programmed path now is the path that they get,” Highley said, adding that the shop now uses one part program for all seven machines instead of individual programs for each machine, and it has reduced hand deburring operations by 98 percent.