Industry leaders address issues and comment on trends in the software and control industry.

Software and control compatibility and emerging technology are the big issues AMERICAN MACHINIST readers want to know more about. According to company executives, integration of software and control systems will become more complete and, if manufacturer's needs are addressed, these new systems will become simpler to install, maintain, and operate.

What steps can the controls industry take to make control retrofits available for the life of a machine tool?

Our experience indicates that what's most important to customers in their decision to retrofit an existing machine tool is the over-all value package provided by the OEM or control supplier. This incorporates requirements beyond just the CNC control. Their expectations include performance enhancements and increased reliability and maintainability. They also include comprehensive installation documentation, manuals, training, installation and start-up services, periodic maintenance, parts availability, and other productivity upgrade package options. Another responsibility of the control manufacturer is to bring the benefits of technology advancements to their customers.

Don W. Sharp

Business Development Manager Vickers Electronic Systems

Controls manufacturers must operate from the premise that the machine-tool user's requirements will change over time. Therefore, they must design and manufacture hardware and software components for extended life, both in terms of durability and adaptability to future needs. The manufacturer that is attuned to customer requirements and advances in electronics technology is poised to develop viable solutions for meeting emerging market demands.

An open-architecture design is the best method for managing changes in technology and market requirements. Open architecture provides a platform that allows a migration path in both hardware and software as technology advances to maintain the machine's productivity level far into the future. It allows open communications with local area networks, other computers, printers, the Internet, and manufacturing cells and systems; and the use of offthe-shelf third-party and custom software. These capabilities provide the versatility and level of sophistication necessary to address manufacturing trends involving product quality, inventory control, machine availability and usage, and agile manufacturing.

Many of our readers wanted to see seamless integration of their CAD, CAM, PDM, and other types of software. What capabilities can they expect to have?

Seamless integration will be a combination of user demand, creative application development, and standardization around Microsoftbased hardware and software. Integration of CAD, CAM and PDM software is just the tip of the iceberg.

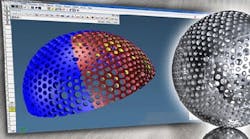

Critical is the integration of technologies which are new to the machine-tool market, technologies which will not only enhance productivity and quality, but also provide improvements in customer service and even generate new service-related markets. Applications such as 3D virtual reality toolpath verification; condition-based messaging via pagers, cell phones, and the Internet; remote diagnostics and preventive maintenance; and connectivity to business systems such as purchasing, sales, MRP, QC, shipping, and more.

Joe Lichtenberg

Director, Technical Marketing Parametric Technology Corp.

Seamless integration becomes critical as companies strive to squeeze more productivity from their product development processes. But seamless integration is more than disparate software packages with different underlying architectures, linked together via translators and equipped with a common user interface. To be truly seamless, the integration must take the form of a relational architecture.

In such a system, the geometry is created once and merely refer-enced by all contributors to the project, guaranteeing that the data is accurate and current, including drawings, tool design, electrodes, NC simulation, CL data, G code, and DMIS data, yet presenting each contributor (such as the NC programmer) with the appropriate interface. In addition, if the geometric model is parametric and flexible, then the associated manufacturing data should automatically update to reflect the design iterations. Another important component of seamless integration is the ability to accurately manage the product data. The PDM system must understand the interrelationships of all of the design and manufacturing data.

Moving forward, the challenge will be to allow this data to inter-face with the enterprise-wide data in both the MRP and ERP environments in order to extract further productivity gains from the product development process.

Yery Camacho

CAM Product Manager Unigraphics Solutions Inc.

The integration of CAD and CAM have been the cornerstones of Unigraphics Solutions' product development for more than a decade. By using a single digital "Master Model" during both the engineering and manufacturing phases, users save time and money and reduce errors. This results from an integrated system which negates the former need of the manufacturing department to regenerate the design data and provides associativity between the design model and the manufacturing processors.

The need for an integrated PDM system does not offer such an obvious advantage. What is clear, however, is without a solid PDM system, access to and control of the great wealth of data generated during the manufacturing phase of product development will be greatly inefficient. An integrated system can help users deal with all this data in a very controlled and logical manner. UGS/CAM is currently extending its technology beyond the NC programming department to the manufacturing shop floor. This will provide capabilities to generate toolpaths in addition to controlling all manufacturing data. We are also developing direct interfaces to areas such as controllers, CMMs, and tooling and ordering systems.

How will the software/controls industry react to the need for more training and technical support?

In doing so, we also look for items that are easily and readily available. An example of that is the air filter we use on our electronic cabinet. We use an off-the-shelf air filter found in most auto parts stores. It's easy to locate and replace, plus it enables the end user to resume making parts faster. In addition, Acu-Rite's worldwide distribution network of fully trained and qualified personnel provides quality after-sales support to end users. Responsiveness when situations do arise is essential. Issues need to be resolved quickly and completely, with the least amount of downtime.

Today the CNC is operated, installed, and upgraded by a select group of CNC control 'experts.' It was not that long ago, that the same could be said of desktop computers. Only experts could operate, install, and upgrade office or engineering automation systems such as word processors or CAD/CAM systems.

MDSI is leading the way to put the CNC control into the hands of the average operator or engineer with little or no CNC control experience. By taking advantage of web-based, multi-media technology and graphical user interface design to enhance ease of learning and use, MDSI is broadening the potential user base of CNC controls. Technology alone will not make a consumer product. Corporate attitude is equally important. The supplier of the CNC control must be willing and able to support the user's desire to be self sufficient and independent. By supplying the necessary technology and business attitude, CNC controls can become 'consumer' products. The learning times for operation, installation, and upgrade will be dramatically reduced— such that nearly any maintenance or manufacturing engineers or knowledgeable workers will be able to operate, install, or upgrade their machine-tool controls when and where they want.

Six years ago, before personal computers were readily utilized on the factory floor, Motoman embarked on creating a DOS, PC-based expert maintenance package named RobotPro. We created the product for one robot model using a licensed, expert software shell. The logic for performing most maintenance and troubleshooting routines was added to the software tree and drawings were added as flip chart style, bitmapped .pic files. The entire product took two years to create from inception to completion, resided on an IBM 386 computer, and sold for $10,000.

Today, Motoman creates an advanced version of our original RobotPro for 15 different products. This system runs in Windows NT and sells for $3,000, a small sum to pay for a full time "service expert" residing 24 hours, seven days a week, at the customer facility.

In the near future, Motoman will introduce a PC-based robot controller. We plan to tie Robot-Pro directly into the PC-based controller allowing the robot to directly advise an operator how to fix alarms through an on-line picture show.

How do you see partnering agreements between software companies and machine-tool manufacturers affecting standardization of open architecture?

Deckel Maho Gildemeister was one of the pioneers in the industry, striving for open architecture on CNC controls. All of our machines are already CE-compliant, and they also have controls with Internet connectivity. Essentially, that means there is a microprocessor chip such as an Intel Pentium processor as the basis for the PC control inside, with a Windows-compatible system for the user interface.

The level of support that will be provided by DMG Netservice is only possible with the open architecture and PC-based controls which are a standard feature on all of our machines built during the past three years. The compatibility allows our experts, sitting at a PC in our facility, to remotely access the data of your program as well as the machine diagnostic functions that can be traced by the PC/CNC control.

Ariel Nosrat

International Marketing Manager Omat Control Technologies Ltd.

Currently, Digitized motion control achieved through CNC technology and digitized geometry and motion definition (CAD/CAM) are well established in the metalworking industry. Tremendous effort has been made to integrate CAD/CAM systems together with CNC controls in an attempt to make metalcutting operations become less dependent on CNC programming in order to reduce production lead times.

Such developments have not been very successful as most machine shops have preferred to separate their planning and production, maintaining that this exercises tighter control over product quality. The advent of excellent DNC link possibilities between CAD/CAM computers and CNC control systems has provided machine shops with the opportunity to achieve some form of integration between CAD/ CAM and CNCs without having to run CAD/CAM software on their CNCs.

In the future, rather than having several software packages bundled together in the control system, users will see distinctively separate but compatible systems, capable of working together where necessary. Moreover, users will be able to run their NC programs on various types of machines as CNC compatible software becomes increasingly independent of CNC platforms.