Maximizing business opportunities often requires new capital expenditures to meet customers’ requirements.

Webco Manufacturing Inc., of Olathe, Kan., (www.webcomfg.com) was looking at new contracts that involved manufactured parts that exceeded its CM measuring capability.

Mike Miller, Webco manufacturing quality manager, said the company was getting new contracts because it had a reputation for quality and on-time delivery, and the option of using outside CM services was eliminated because added transportation and handling costs added unwanted time and expense that cut its profit margins and control of its delivery process.

Miller said the company needed in-house CM measuring capability, and found it needed a new machine to do the work it had secured.

The company replaced a remanufactured CM it had recently acquired with a new Wenzel 12.30.10 that it found to be priced competitively with similar rebuilt machines.

The Wenzel LH 12.30.10 has a measuring range of 1200 mm (X axis) (47.24 in.) by 3000 mm (Y axis) (118.11 in.) by 1000 mm (Z axis) (39.37 in.) with a standard accuracy with Renishaw TP200 Probe of U3 2.6+L300.

The machine is equipped with a Renishaw PH10M/ TP200 probe and a Wenzel WPC 2030 universal CM controller that combines the latest CNC technology with the integration of all Renishaw heads with touch trigger probes.

Large Wenzel CM machines have a selfstabilizing design with integrated pneumatic vibration dampeners that Wenzel said eliminates the need for an isolated foundation. With the X bridge and Z ram manufactured of granite, Wenzel said identical thermal behavior can be predicted for all axes and accuracy can be maintained.

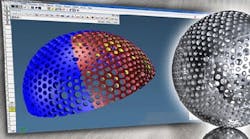

The machine is equipped with the trademarked OpenDMIS software product that takes the integrates CAD data with the CM programming and measurement process seamlessly to provide the user with a high level of power, precision and productivity at the single click of the mouse.

Drag and dropping features from the database area into the adjacent programming window automatically generates underlying DMIS 5.0 code together with probe and alignment definitions, and complex CM programs can be created in a few minutes and simulated, utilizing the powerful simulation and collision avoidance tools standard in OpenDMIS.

The software product incorporates the use of dynamic sensitive tool bars, action icons and context sensitive work areas. The graphics view port remains freely visible at all times, maximizing operating efficiency. There are no windows to close and no cascading windows, and typical screen crowding is eliminated. Also, there are is no drill-down functionality.

The Wenzel CM was provided by Xspect Solutions, Inc. (www.xpectsolutions.com) of Wixom, Michigan, a wholly owned subsidiary of Wenzel Gmbh of Germany.

Separately, Wenzel has added a line of Coordinate Measuring Machines that are designed and developed to solve shop floor CM implementation issues related to the measurement of small and medium size manufactured parts.

The Wenzel Smart Series of CMs have a smaller footprint and measuring range than the company’s other machines.

The “Smart Mini” has a measuring range of 300 mm (11.81 in.) by 450 (17.72 in.) by 400mm (15.75 in.)

The company said it was designed and built to exacting and rugged machine tool standards, and uses fine grain, nativeblack granite to provide thermal stability, dynamic performance, tremendous stiffness and natural vibration dampening. It has precision linear guideways that are protected and covered, carbon fiber scale mounts.

Wenzel opened a new 24,000 North American manufacturing facility in Wixom, Mich., in October. The two-story facility houses the company’s engineering, administrative and production operations.