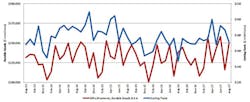

U.S. manufacturers purchased $196.23 million worth of cutting tools during August, a 14.8% rise over July’s result and 11.6% more than the August 2016 consumption total. The figures portray the steady improvement in domestic manufacturing activity, a reading that is even more evident in the year-to-date total, $1.462 billion for January-August, which is 7.7% higher than last year’s eight-month total.

Cutting tools are one of the principle consumable products for manufacturers — machine shops and other. Thus, consumption of cutting tools presents a quantifiable index to the current state of manufacturing activity, comparable to durable goods shipments.

Each month the U.S. Cutting Tool Institute (USCTI) and AMT – the Association for Manufacturing Technology. The Cutting Tool Market Report (CTMR) compiles data supplied by participating companies, who represent the majority of the U.S. market for cutting tools.

The sustained expansion of domestic manufacturing is also evident in the AMT’s U.S. Machine Tool Orders report, which is a leading indicator of manufacturing activity by tracking the capital investments made by U.S. manufacturers.

“The U.S. cutting tool market continues to benefit from a growing domestic economy. 2017 to 2016 comparisons are all positive,” stated USCTI president Steve Stokey. “Current indicators such as the PMI, industrial production, and consumer confidence point to continued positive growth for the industry as we move into 2018.”