New slotting cutters from Iscar Metals are available with grooving inserts or slotting inserts.

Seco's MF5 chipbreaker generates low cutting forces to allow for high feedrates.

LC insert geometry from Sandvik Coromant improves chip evacuation when cutting low carbon steels.

Guhring's new coolant-fed carbide end mills have radial coolant-delivery ducts

Chip control is a major concern because a buildup can cause hammering and chatter and has a deleterious effect on tool life, cutting forces and surface finish. Several new inserts, chipbreakers and cutting tools have been introduced that help to reduce chip accumulation.

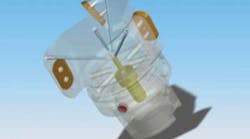

Iscar Metals Inc. (www.iscarmetals.com) has introduced two new Tangslot slotting cutters that are designed to be used with LNET 12 inserts that have two right-hand and two left-hand helical cutting edges. The company says the positive, helical rake face chipformer on the inserts reduces cutting forces and reduces power consumption by 15 percent to 25 percent. It also directs chips away from the cutting area leaving the side surfaces of machined parts unscratched. Chips are directed inward toward the center of the cutter instead of outward toward the sidewalls. Two types of inserts are available: One with rounded corners for grooving, and a second with chamfered corners for slotting. Iscar says the insert configuration reduces chatter and improves tool life.

The new slotting cutters are available as FDN flanged-type cutters or as SDN disk-type cutters. The width of the cutters can be adjusted by the use of cartridges and different width inserts. The available diameters include 100 mm to 250 mm (3.937 in. to 9.842 in.) and width sizes from 6.0 mm to 14.6 mm (0.236 in. to 0.575 in.).

Tangslot cutters can be used for grooving and parting operations in applications such as automotive bearing caps, steering knuckles, and connecting rods and in other general slotting applications.

Seco Tools Inc. (www.secotools.com) says its new crown-shaped MF5 chipbreaker increased tool life in 67 percent of field test applications and improved chip control in 41 percent of the tests. The company says the chipbreaker is optimized for mediumfinishing operations associated with near-net machining. The groove generates low cutting forces and allows for high feedrates when the depth of cut is between 0.020 in. and 0.100 in. (0.5 mm and 2.7 mm). The MF5 chipbreaker has a three-pronged, crown shape with chip deflectors and cooling ditches that are beneficial at low depths of cut and with ultra-high pressure coolant. Also, Seco says its open geometry reduces cutting forces. The chipbreaker has a ground island that improves insert seating, and is designed to conduct heat away from the workpiece and cutting edge.

The MF5 is available as either positive C and standard W-style inserts in grades TK1000, TK2000, TP1000, TP3000 and DurAtomic TP2500. In a roughing operation conducted on a steel rock drill (42 to 45 HRC) with the MF5 with grade TK1000, tool life increased 500 percent as compared with a competitive chipbreaker. In a similar test using MF5 and grade TP2500, productivity increased 55 percent and tool life increased 360 percent as compared with an M5 chipbreaker in grade TP2000.

Sandvik Coromant's (www.coromant.sandvik.com/us) new LC insert geometry prevents frequent chip jamming when cutting difficultto-machine materials. By lowering the risk of chip jamming, the LC insert geometry reduces the risk that chip accumulation can pose to the cutting tool and surface finish of a machined low-carbon steel component. The use of wiper inserts allows for increased feedrates. The low carbon LC geometry is available in GC4225, GC1525 and GC2025 grades of turning inserts.

Guhring Inc. (www.guhring.com) has introduced the Series 3365 Rough-Tech 48 coolant-fed carbide end mill with a four-flute design that produces small, easy-to-manage chips. The company says the 3365 series delivers aggressive speeds and feeds when slot and rough milling steel, while removing maximum stock with minimal deflection horsepower. It is also suitable for titanium and titanium alloys, aerospace materials and nickel-based alloys.

The company also has introduced the three-flute carbide Series 3376 AlumiTech LR and the Series 3364 RoughTech Alu end mills for aluminum and aluminum alloys. All three end mill series are available as stocked standards in diameters from 6.0 mm to 20.0 mm (0.236 in. to 0.787 in.).