A strategic alliance between Vykor and Iscar, Arlington, Tex., brings advanced machining technology in support of Vykor's Engineered Part Management (EPM) sourcing solutions.

With Vykor EPM solutions, manufacturing knowledge integrates into a collaborative platform and lets OEMs and suppliers in the aerospace and semiconductor capital-equipment industries quantify the investment of advanced manufacturing technologies and processes. Iscar tooling, modeled in Vykor's software when appropriate best-in-class criteria are met, gives visibility to the ROI of new Iscar cutting technology.

Vykor Inc.

Renton, Wash.

vykor.com

Expanded collaboration

Mitsubishi Heavy Industries America expands its collaboration with Yamazen as its major distributor of Mitsubishi machine-tool products in the U.S. Yamazen now assumes responsibility for all Mitsubishi machining center, large machine, and grinder products. Yamazen's role is that of importer and distributor providing logistics, warehousing, and national parts and service support.

Yamazen Inc.

Schaumburg, Ill.

yamazen.com

Cast and ductile-iron cutters

The cutter program includes a 45° lead-angle roughing cutter, three 30° lead-angle cutters, a 30° lead-angle roughing cutter, and two 30° lead-angle finishing and semifinishing cutters. One of the 30° lead-angle finishing and semifinishing cutters provides reduced cutting pressure for light-duty machines and thin-wall parts. All cutters in the line reportedly offer low tooling costs because they use two-sided, hexagonal inserts with 12 cutting edges, as compared with six or eight cutting edges on competitive tools. Various coatedcarbide grades are available for the M750 Hexacut milling program.

U.S. CUTTING TOOL INSTITUTE BILLINGS INDEX | |

Index for September '03—August '04 | |

| September...$125,456,973 .......115.4% | March ........$154,823,146 .......145.4% |

| October ......$132,331,224 .......121.3% | April...........$142,985,844 .......134.7% |

| November ..$116,384,449 .......107.1% | May............$135,776,786 .......127.8% |

| December ...$121,200,994 .......111.7% | June............$150,760,547 .......141.2% |

| January.......$126,819,295 .......119.2% | July.............$136,045,837 .......126.8% |

| February.....$130,560,000 .......123.0% | August........$151,299,780 .......142.9% |

Kennametal Inc.

Latrobe, Pa.

Kennametal.com

Extension to boring-head range

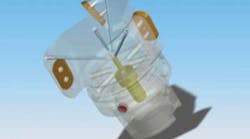

Six EWB heads (32, 41, 53, 68, 85, and now 100), covering a diameter range of 1.260 to 6.024 in., incorporate KA connections and fully automatic balancing that occurs with diameter adjustment. Dials on the EWB heads eliminate parallax errors and graduate in 0.0005-in. increments. Kaiser's locking system prevents tool carrier or the counterweight movement caused by locking action or centrifugal force at high speeds.

BIG Kaiser Precision Tooling

Elk Grove Village, Ill.

bigkaiser.com