Shop Surfs For RFQs

Travis Sherwood finds machining work for his shop from the comfort of his home computer.

After enduring several years of working for five or six large manufacturing companies, Travis Sherwood struck out on his own and started a machine shop in Havana, Kan. He literally built the place with his own hands – laid forms, poured concrete and moved in machine tools. From the start of the business, Sherwood declared that he was not going to go door-to-door or use a manufacturer's rep to find work. What he did use was Internet sourcing from a site called Mfg.com.

Sherwood said Mfg.com was part of his original job plan. "I wanted to be able to sit in my house, look at my computer and quote work from anywhere. Now, I bid on RFQs in Tulsa, Phoenix, California and Canada. Since joining Mfg.com, I've been awarded 82 RFQs and have also found a considerable amount of off-line work as well," said Sherwood.

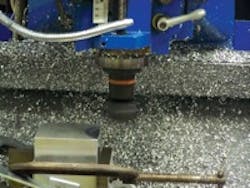

The shop processes pretty much anything that comes across the line, such as plastics, aluminum, stainless steel, conventional steels, copper and brass. It primarily serves the aerospace industry, with the majority of parts being made for researchand development. However, Sherwood also is involved in the medical field, doing what he refers to as "pretty nondescript but highly tolerance-specific parts for procurement machines." Part surface-finish tolerances at Sherwood's shop typically run in the Ra 32 range, and size tolerances can be as tight as +/-0.0003 in.

Sherwood recalls one of his earliest RFQs. "I think it was the second job I was awarded," he said. "The guy was a freelance engineer who went from place to place getting certain parts to make, and I did one job for him. This was unusual and stayed with me because it wasn't like working for a company.

I wasn't even sure if I could make the part for him. But in the end, I did, and we had great communications. Since then, he's worked with me exclusively for custom-made machine parts. From that one engineer, I received a $7,000 order, then another order for the same parts amounting to $12,000."

In addition, Sherwood plans to quote jobs from Europe now that Mfg.com has merged with SourcingParts, a European Internet sourcing site.