In the supply chain of precision parts there are two zones: CAD and CAM. CAD is occupied by designers, visionary individuals who see machined parts as elements of larger, more integrated systems. CAM is the territory of machine tool operators, and programmers – people whose primary interest is making those parts, as many as possible, as quickly and cost-efficiently as possible.

All these people have a lot to discuss about the way their projects move from one zone to the next, from design to manufacturing, but they have not had many effective channels for communication. This is changing rapidly, because all of manufacturing is changing. It’s getting smarter.

By taking advantage of integrated technology to optimize the manufacturing process, Smart Manufacturing has the potential to increase speed to market and improve product quality. However, Smart Manufacturing can only revolutionize the product manufacturing process if it is connected with, and works in sequence with, the product design phase.

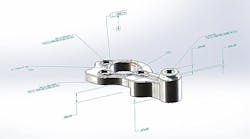

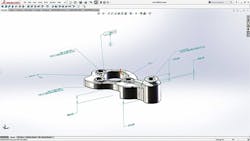

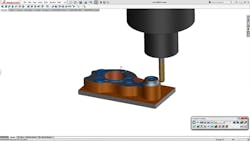

SolidWorks, one of the primary CAD platforms for precision parts, has been building a Smart Manufacturing ecosystem with tools like Costing, Inspection, and Model-Based Definition (MBD). Recently, at its annual users and developers conference SolidWorks World, Dassault Systémes announced the next logical step - SolidWorks CAM, a 2.5-axis milling and turning solution powered by CAMWorks. With SolidWorks CAM, users will be able to check their components for manufacturability earlier in design process, saving time redesigning later on. Using an integrated CAM system makes it easier to learn and understand how your components will transition from bits to atoms. Integrated CAM also allows for automatic updating of toolpaths because the CAM system can read changes as you make updates to parts.

SolidWorks CAM will allow users to program in either part or assembly environments. In addition, SolidWorks CAM will be able to work with configurations of components to expedite the programming process.

The foundation of SolidWorks CAM is Knowledge-Based Machining (KBM). KBM will allow companies to define standard machining strategies that can be used by everyone within their organization, from quoting to programming. Consistency in workflow will reduce errors and improve quality during the design-to-manufacturing process.

SolidWorks CAM will be available for Beta starting April 1, 2017. The commercial release will come with the introduction of SolidWorks 2018.

Tony Glockler is the co-founder and CEO of SolidProfessor, an online learning companyGlockler’s past contributions to AmericanMachinist.com have addressed trends influencing the future of reshoring, training priorities for manufacturing positions and strategies for improving engineering productivity.