A new programming “strategy” called Vortex, for high-speed area clearance, will be the major enhancement for the 2013 release of Delcam’s PowerMILL CAM system for high-speed and five-axis machining. The new release will be introduced in September at IMTS 2012, the CAM developer announced. The new functionality also will be added to new releases of Delcam’s FeatureCAM software for feature-based programming and the PartMaker system for programming Swiss-type lathes and turn-mill equipment.

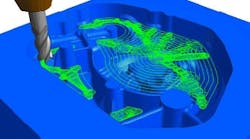

Delcam explained that Vortex, for which it has a patent pending, was developed to gain the maximum benefit from solid-carbide tooling, in particular for those designs that may tolerate deeper cuts using the full flute length as the cutting surface. It can be used for two- and three-axis roughing, three-plus-two-axis area clearance, and for rest machining based on stock models or reference toolpaths.

Like Delcam’s other roughing strategies, Vortex toolpaths are calculated to give more efficient machining by following the shape of the part and by keeping air moves to a minimum. This is particularly important for rest machining operations.

One “fundamental problem” with conventional area-clearance strategies — the CAM developer elaborated — is that the optimal cutting conditions occur only with straight-line cuts: Any internal corners within a model significantly increase the engagement angle of the cutter. To protect the cutter, this increase needs to be balanced by setting a lower feed rate. Then, the user then has to choose whether to use this lower rate over the whole toolpath, which will increase machining time; or to vary the feeds and speeds as the cutter moves around the model, and thereby increase wear on the cutter.

In contrast to other high-speed roughing techniques that aim to maintain a constant theoretical metal-removal rate, Delcam noted that Vortex derives toolpaths with a controlled engagement angle for the complete operation. “This maintains the optimum cutting conditions for the entire toolpath that would normally be possible only for the straight-line moves,” it reported. “As a result, the cutting time will be shorter, while cutting will be undertaken at a more consistent volume-removal rate and feed rate, so protecting the machine.”

Delcam explained that because Vortex toolpaths have a controlled engagement angle, tools will never be overloaded and therefore will achieve their maximum tool life. Shock loading caused by changes in the contact angle is minimized, preventing chipping of the flutes. Also, it noted that the stability of the cutting conditions gives more consistent edge temperatures, so prolonging the life of the tool coating and removing heat damage to the surface of the part.

Also contributing to longer tool life will be the program’s ability to use stepdowns of up to two or even three times the tool diameter, which will spread the tool wear evenly over the cutting surface.

“Anyone using the Vortex strategy will be able to hear the difference immediately,” claimed product manager Mark Forth, with Delcam’s Advanced Manufacturing Solutions. “Conventional roughing produces a sound of varying pitch, which indicates tool overload and chatter, while Vortex roughing gives a constant pitch, showing that the tool is operating under consistent conditions. Users will also be able to see the difference in the regular size and thickness of the chips produced, providing further evidence of the consistency of the cut.”

The Vortex toolpaths also carry the general advantages of PowerMILL, which include support for 64-bit computing and multi-processor operation to minimize calculation times, plus the comprehensive options for leads and links.

They can be used in association with the step-cutting strategy introduced in PowerMILL 2012 R2, too. This minimizes the terracing that may result from using a large stepdown by moving back up the part, automatically generating extra toolpaths, to remove additional material at intermediate slices. It optimizes the amount of material that can be removed with a single tool, Delcam indicated, and helps to maintain a more consistent removal rate by increasing the feed rate for the intermediate slices.