IF ACADEMIA HAS ITS WAY, SHOPS WILL TURN TO THE INTERNET TO SIMULATE AND OPTIMIZE THEIR MILLING PROCESSES.

McMaster's simulation program provides scheduled feedrates under chip-load constraint (a) and force constraint (b).

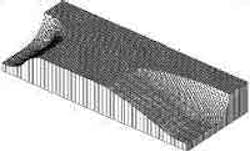

Predicted cutting forces under chip-load constraint (a), force constraint (b), and a nominal feedrate of 0.002 in./tooth (c). Each spike represents maximum force during a single roughing pass. Feed scheduling using force constraint reduced machining time by 33.7%. Under force constraint, force is regulated at 450 N to ensure stable machining.

At one time, expensive process trials were the only way to predict cutting forces and tool deflection created during milling operations. However, shops now have an intriguing alternative. New process simulation and optimization techniques — developed by various universities and available over the Internet — let shops analyze the effect of various process parameters on milling productivity and part quality..

With this information, these shops can optimize milling operations process parameters such as feeds, and toolpaths.

One of the prolific manufacturing research groups accessible on the Internet is that of Mc-Master University, Hamilton, Ontario. Mc-Master has developed a multi-axis milling program that integrates advanced process-simulation software with state-of-the-art multi-media and Internet technologies to create a virtual process-optimization environment.

In this environment, a manufacturing engineer is guided through a process of simulating, evaluating, and optimizing process parameters and operational sequences. The simulation predicts cutting forces and resulting tool deflections. The effects of these parameters are evaluated in terms of desired product features such as dimensional accuracy, surface quality, tool life, and reduction of cost and lead time.

The program accurately predicts instantaneous chip load (cross-sectional area of tool/work inter-face), which relates to cutting force and load per unit length on the tool cutting edge. Inputs for the simulation are a cutter location file and tool geometry. Outputs are instantaneous chip load, cutting forces, and tool deflection.

Modeling the process

McMaster’s multi-axis milling simulation and optimization program incorporates a two-part modeling methodology — a geometric and a mechanistic force modeler.

The geometric modeler defines the tool cutting edge, the local surface topology of the part, and the tool/part inter-action during machining. The tool/part inter-action during machining is determined from the defined local surface topology and the instantaneous position of the cutting edge.

Tool/part interaction information defines the integration limits for the mechanistic force modeler. The force modeler estimates the normal and frictional differential forces acting on the rake face and cutting edge. A summation of these forces leads to a determination of instantaneous force acting on the in-cut cutting edge of the tool.

Feed scheduling

In the multi-axis milling program, process constraints (specific to milling) are used to adjust feedrate according to the type of machining operation. This is called feedrate scheduling. Predetermined process limits such as shank and tooth breakage constraints, chatter limits, and surface dimensional error constraints can be satisfied by imposing either a maximum force constraint or a maximum chip-load constraint.

The maximum force constraint is imposed for rough machining or to limit tool defections. This eliminates force spikes during cutting that could either chip or break the cutting edge. For semifinishing or finishing operations, the maximum chip-load constraint is imposed to control surface finish and/or increase productivity. At user-specified intervals along the toolpath, instantaneous cut geometries and cutting forces are determined with the models and feedrate scheduling performed accordingly to determine optimum feedrate.

An exercise in boosting productivity

To illustrate the practical impact of the multi-axis milling simulation and optimization program, consider producing a complex, airfoil-like surface by a 3-axis milling process. To perform a simulation, a user must input parameters related to the workpiece, cutting tool, and tool-path. Workpiece input parameters are the stock dimensions and material type (titanium Ti6A14V, in this case). Cutting tool input parameters are the tool type (ball), diameter ( 3 / 4 in.), and material (solid carbide). Feedrate scheduling is applied to the rough machining operation for this part and is presented for both maximum chip-load and maximum force constraints.

Forces are predicted for the different simulation runs under chip-load constraint, force constraint, and for a nominal feed of 0.002 in./tooth. The force profile generated is the maximum force at each time step. Each spike represents a single roughing pass; complete rough machining of this part requires 30 passes.

The benefit of feedrate scheduling on total machining time is obvious from the results of the simulation. Time to rough machine the part using the nominal feed is 295 sec. Time to rough machine the part with feedrate scheduling using a chip-load constraint is 210 sec, a reduction in machining time of 28.7%. Machining time using feedrate scheduling with a force constraint is 195 sec, a 33.7% improvement. Also, in this case, force is regulated to 450 N to help ensure machining stability.

MTAMRI: An Internet source of milling technology

More than 30 industrial, government, and university partners are members of MTAMRI. Each of the university partners has strong, well-established research and education programs in technologies related to machine tools and has significant ongoing support and cooperative relationships with the machine tool industry. Several MTAMRI university partners are involved in significant, ongoing, research related to milling technologies.

MTAMRI is more than an experiment in cross-university cooperative research. The program has a faculty, specific joint-research programs, a graduate curriculum of course offerings, and intimate industry involvement in research and deployment activities including beta testing and factory-floor implementation. It complements and participates in several other national efforts that impact the machine-tool industry, including the DOE National Machine Tool Partnership, the National Center for Manufacturing Sciences, and AMT—The Association for Manufacturing Technology.

A milling-process testbed

MTAMRI has developed a series of software testbeds — Internet-based interfaces to application programs for modeling machining systems. One of these is EMSIM, a software application that simulates an end milling process. Application areas for this testbed include fixture design, tool selection, generalized process planning with toolpath specification, machine tool design, chatter and vibration control, and optimal selection of machining conditions for improved precision and accuracy, including flatness, cylindricity, and dimensional stability in general.

The EMSIM testbed is capable of simulating a step cut, step cut with draft angle, and corner cut. A dynamic model of the end milling process is included in the software testbed. The model lets a user predict vibration and chatter assuming a rigid workpiece and flexible tool. Simulating multiple passes is done using the first cut's surface error values as input parameters for the second cut.

User inputs for the EMSIM simulation include: cut geometry, workpiece material, end mill geometry, and machining conditions (speeds and feeds). Outputs include: cutting forces, cutting power, and part/cutter deflections.

University research

The following is a brief description of milling and related machine tool research underway at several of the various university members of MTAMRI. Additional information on programs can be obtained from the principal investigator who manages the program at each university.

University of California—Berkeley: Berkeley manufacturing researchers contributed to MTAMRI in three specific projects: process modeling, process planning, and environ-mentally conscious manufacturing.

The process modeling was under the supervision of Professor David Dornfeld and was linked to his Consortium on Deburring and Edge Finishing (CODEF), an industry-supported research effort on burr-formation modeling and software development for burr minimization. CODEF work in MTAMRI centered on drilling and milling, and CODEF contributed both basic work on finite-element modeling analysis of burr formation in milling and drilling (as well as a burr expert database for assisting process planners in choosing machining conditions to minimize burrs in milling and drilling). This work has also led to the development of a "burr control chart" for burr formation prediction in milling.

The process planning activity was linked to Professor Paul Wright's Cybercut Internet-based CAD/CAM rapid prototyping project. This comprehensive manufacturing process analysis service for macro and micro planning — interactively from a CAD station or network browser linked via the Internet — used the EMSIM end milling simulation program for part of the process planning. In addition, milling burr generation predictive software, also from CODEF, was incorporated for edge quality process planning in Cybercut as part of the project.

Finally, the environmentally conscious manufacturing work of Professor Paul Sheng as part of the Berkeley Consortium on Green Manufacturing was also linked into the process planning activities of Cybercut. Focusing on cutting fluid minimization, the "green" work developed algorithms for evaluation of cost-benefit tradeoffs of modifying the process plan for milling operations by using the cutting fluid more effectively and by adjusting the sequence of processes or the cutting conditions to lower fluid volumes.

Principal investigator: Dr. David A Dornfeld, [email protected]

Purdue University: Purdue's Manufacturing Laboratory is currently working on several research projects related to milling:

- Modeling and simulation of machining processes: Cutting force and vibration are important variables affecting the performance of machining processes. The goal of this project is to develop a comprehensive mechanistic model incorporating workpiece properties, cutting tool geometry, and machine dynamics. The project has established comprehensive models and a computer program developed to simulate the cutting process.

- Machining chatter modeling and prediction: The goal of this project is to develop accuracy-prediction capabilities for machining chatter. The group has developed a comprehensive and accurate stability prediction algorithm, based on a frequency domain approach. The model is applicable to complex milling processes and is computationally efficient.

Adaptive control of milling processes: Currently, fixed controllers are designed for milling machines, and machining performance diminishes as the cutting parameters vary. Furthermore, varying gains and dynamics require conservative feedrate settings for fixed control systems. Maintaining desired cutting forces prolongs tool life increasing productivity. To alleviate these problems, an adaptive controller has been designed that will maintain a constant cutting force for milling operations by controlling the feedrate of the table.

Mechanics of high-speed machining: In this project, the basic mechanics and benefits of high-speed machining are studied. Experimental investigations are performed on the latest in high-speed milling machines with materials including aluminum and high temperature alloys. Chip morphology, the resultant residual stresses, and tool wear are stud-ied both by numerical simulation and experiments.

Principal investigator: Dr. Y. C. Shin, [email protected]

University of Illinois at Urbana-Champaign: The Machining Process Modeling program offers a comprehensive, scientifically based method of predicting a wide range of machining process performances including cutting forces, dimensional and form errors, surface finish, cutting process stability, and vibration and chatter. A short-term goal is the development of simulation software for the face milling process that is capable of predicting final process performance.

Other MTAMRI programs include agile fixturing, hybrid machining, environmentally conscious machine tool systems, and drilling technology. The development of a comprehensive software environment called the Virtual Machine Tool Software Testbed simulates and evaluates a range of processes executed on alternative topological machine configurations. A goal is to explore advanced new technologies and active control methods for error compensation and vibration suppression.

Principal investigator: Dr. R. E. DeVor, [email protected]

Learning moreThe work carried out at McMaster University on the simulation and optimization of multi-axis milling processes* illustrates the interactive capabilities of Internetbased manufacturing research efforts. The Internet implementation of this program is integrated with other related machining technologies at the Centre for On-Line Manufacturing Optimization (COMO) at the Mc-Master Manufacturing Research Institute (MMRI). Information on metalcutting research at the institute can be obtained from its director, Dr. M. A. Elbestawi, [email protected] * Based on "Internet Based Implementation of Multi-Axis Milling Process Simulation and Optimization," T. Bailey, P. Renton, M. A. Elbestawi of McMaster University and L. Chen, C. Guo of United Technologies Research Center, a paper accepted for publication at ICME 2000, International Seminar on Intelligent Computation in Manufacturing Engineering. June 21-23, 2000, Naples, Italy. |