Geometric Technologies Inc. has released CAMWorks® 2011, the latest version of its solid-based CNC software program, which it intends to be a “focused upgrade” of the control platform, with enhancements for automation and new capabilities for knowledge-based machining information, and “smarter” tool paths, among other improvements.

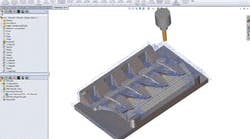

Among the new features in CAMWorks 2011 is VoluMill®, the ultra high-performance toolpath plug-in engine for high-speed milling for 2.5-axis and 3-axis roughing operations. It is especially effective for machining prismatic parts and complex 3-D shapes as its algorithms result in more intelligent toolpaths to machine pockets, slots, and arbitrary shapes. It can be used with any material, including the hardest metals. The result is increased efficiency and utilization of machines, tools, labor and materials. For mold and die machining, Geometric has introduced an optional electrode design solution called ElectrodeWorks™ that automates all aspects of the calculation and design of EDM electrodes, including design, management, documentation and manufacturing. Because its integration with SolidWorks/CAMWorksSolids is “seamless,” according to Geometric, it ensures complete parametric association of data.

The CAM’s Feature Recognition function, which automatically identifies areas to be machined, has been upgraded to locate more features while decreasing computation times by more than 50% over previous CAMWorks versions. As part models become increasingly complex, recognizing more features in less time represents a significant timesaving for the NC programmer. The proprietary technology database (TechDB™) that stores and applies knowledge-based machining information has been enhanced to simplify the process of creating best machining practices. The improved interaction will result in greater use of the knowledge-based machining capabilities of CAMWorks, and will reduce potential errors in machining information, Geometric indicates.

Additional enhancements with CAMWorks 2011 include improved performance and enhanced feature recognition of slot features with fillet and taper, as well as slots with islands. Users can define customized turn inserts when it is not possible to completely machine a turn part using a standard turn insert line diamond, square, etc. Such custom turn inserts can be defined for inner and outer diameters. Earlier versions of CAMWorks did not provide flexibility to define work-in-process for turning operations, but the developer asserts that CAMWorks 2011 provides the option to define the operation to be considered as the work-in-process within the entire operation.